Scaffolding stays up in Saudi Arabia using strong materials and skilled construction. Safety standards are strict, and workers follow precise guidelines.

In Saudi Arabia, construction projects rely heavily on scaffolding. It provides a secure platform for workers and materials. The hot climate and varying terrain require special attention to detail. Builders use quality materials like steel and aluminum. They ensure the scaffolding is stable and can withstand harsh weather.

Skilled workers assemble and inspect the structures regularly. Safety is always a priority, with strict regulations in place. This ensures that scaffolding remains reliable and secure throughout the project. Understanding these factors can provide insight into the construction practices in Saudi Arabia.

Introduction To Scaffolding In Saudi Arabia

Scaffolding is essential in the construction industry. It provides support and access during building projects. Saudi Arabia has a unique approach to scaffolding, influenced by its history and modern needs.

Historical Background

Scaffolding in Saudi Arabia has deep roots. Traditional methods used wooden structures. These were simple but effective. Builders used local materials like palm wood. The designs were basic, focusing on functionality.

Ancient builders had to be innovative. They adapted to the harsh desert climate. Their scaffolding designs reflected this. They ensured stability against strong winds and sandstorms.

Modern Applications

Today, scaffolding in Saudi Arabia uses advanced techniques. Metal scaffolds are common. They are stronger and more durable. Modern designs focus on safety and efficiency.

Construction projects are larger now. Skyscrapers and mega-projects are the norm. Scaffolding must support these massive structures. Engineers use advanced materials and technology. This ensures scaffolding stability even at great heights.

Safety standards are strict. Regular inspections and maintenance are mandatory. Workers receive special training. This ensures they can handle complex scaffolding systems. Innovation continues to drive the industry forward.

Credit: www.skisoutheast.com

Materials Used In Scaffolding

Scaffolding is essential for construction projects in Saudi Arabia. It provides support and access to areas that are hard to reach. The materials used in scaffolding play a crucial role in its stability and safety. Understanding these materials can help ensure the scaffolding stays up securely.

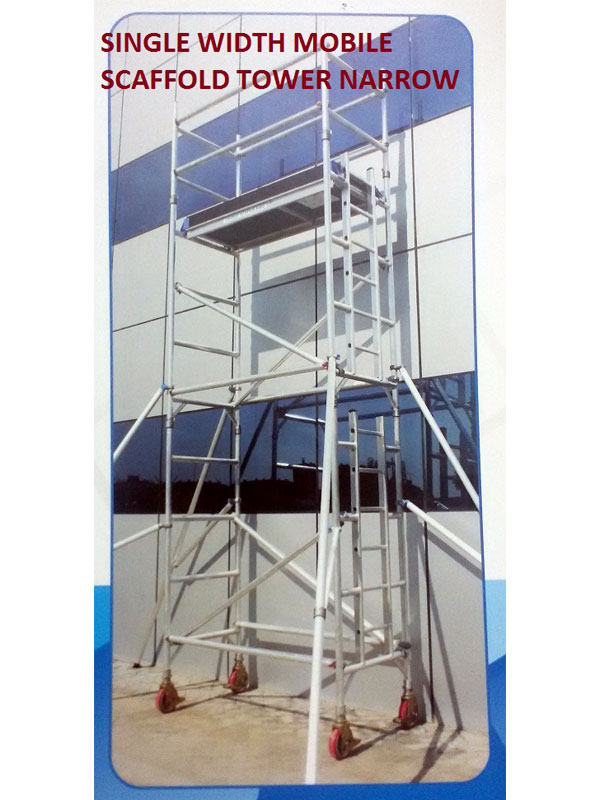

Types Of Materials

The primary materials used in scaffolding are steel and aluminum. Steel scaffolding is strong and durable. It is often used for heavy-duty projects. Aluminum scaffolding is lightweight and easy to transport. It is suitable for smaller projects and quick setups. Both materials have their advantages depending on the project’s needs.

Material Properties

Steel is known for its strength. It can support heavy loads without bending. This makes it ideal for larger structures. Steel is also resistant to fire, which adds an extra layer of safety. Aluminum, on the other hand, is much lighter. This makes it easier to move and set up. Despite being light, aluminum is still very strong. It can support significant weight without compromising stability.

Both steel and aluminum are resistant to corrosion. This is important in Saudi Arabia’s climate. The materials need to withstand extreme heat and occasional rain. Corrosion resistance ensures the scaffolding remains safe and durable over time.

Another important property is the ease of assembly. Both materials allow for quick and secure connections. This helps in building the scaffolding structure efficiently. Proper assembly is key to the stability and safety of the scaffolding.

Design Principles

Understanding the design principles behind scaffolding is vital. These principles ensure the structure remains stable and safe. In Saudi Arabia, scaffolding must endure extreme weather conditions. It must also comply with strict safety regulations. Let’s explore the key design principles that keep scaffolding secure.

Load-bearing Calculations

Accurate load-bearing calculations are essential. Engineers calculate the weight scaffolding can support. This includes the weight of workers, tools, and materials. They also consider the wind and other environmental factors. These calculations prevent overloading and potential collapses.

Safety Considerations

Safety considerations are critical. Scaffolding must have secure guardrails and toe boards. These prevent falls and injuries. Regular inspections are mandatory. They ensure all components are in good condition. Proper training for workers is also essential. It helps them follow safety protocols effectively.

Credit: www.amazon.sa

Weather Adaptations

In Saudi Arabia, scaffolding faces unique weather challenges. The extreme heat and strong winds demand special adaptations. Let’s explore how scaffolding remains stable and safe in such conditions.

Heat Resistance

Saudi Arabia is known for its high temperatures. Scaffolding materials must be heat-resistant. Steel is a common choice because it can withstand the heat. Aluminum is also used due to its lightweight nature. Both materials perform well in extreme temperatures.

Heat can cause materials to expand. This expansion can weaken joints and connections. Engineers use special joints that allow for this expansion. This prevents the scaffolding from losing its strength.

Wind Load Management

Strong winds are another challenge for scaffolding in Saudi Arabia. To manage wind loads, scaffolding designs include extra bracing. Bracing helps to distribute the wind force. This keeps the structure stable.

Engineers also use wind barriers to reduce the impact of strong gusts. These barriers are placed strategically around the scaffolding. They break the wind and reduce its force on the structure.

Here’s a table that shows common wind load management techniques:

| Technique | Description |

|---|---|

| Extra Bracing | Provides additional support to withstand wind forces. |

| Wind Barriers | Reduces wind impact by breaking strong gusts. |

| Anchoring | Secures scaffolding to the ground to prevent tipping. |

Anchoring is also crucial. Engineers anchor scaffolding to the ground or nearby structures. This adds another layer of stability against wind forces.

Innovative Techniques

Scaffolding in Saudi Arabia employs innovative techniques to ensure safety and efficiency. These techniques are vital in the construction industry. From modular systems to advanced anchoring methods, scaffolding remains stable and secure. Let’s explore some of these cutting-edge techniques.

Modular Systems

Modular systems have revolutionized scaffolding. They are easy to assemble and disassemble. Each module fits perfectly with others, creating a strong structure. Workers can set up these systems quickly, saving time.

A key benefit of modular systems is their flexibility. They can adapt to various building shapes and sizes. This makes them ideal for projects in Saudi Arabia, where architecture can be unique.

| Feature | Benefit |

|---|---|

| Easy Assembly | Reduces setup time |

| Flexibility | Fits different structures |

Advanced Anchoring Methods

Advanced anchoring methods ensure scaffolding remains stable. These methods involve securing the scaffold to the building. They use strong materials like steel and advanced fasteners.

Several techniques are used for anchoring:

- Through-Bolting: Bolts pass through the wall, securing the scaffold.

- Dead Weight Anchors: Heavy weights keep the scaffold in place.

- Adjustable Anchors: These can be adjusted for different surfaces.

These methods are crucial in windy conditions common in Saudi Arabia. They ensure the scaffold does not move or fall.

Case Studies

Scaffolding plays a crucial role in the construction industry. In Saudi Arabia, it is vital to understand how scaffolding stays up, especially in challenging environments. This section explores case studies of iconic projects and the challenges overcome to ensure stability.

Iconic Projects

Saudi Arabia is home to several iconic construction projects. One notable example is the King Abdullah Financial District in Riyadh. This project required extensive scaffolding to support its towering structures. Engineers used advanced techniques to ensure safety and stability. They employed high-quality materials and precise calculations.

Another significant project is the Jeddah Tower, set to be the tallest building in the world. The scaffolding for this project had to withstand extreme heights and wind pressures. Engineers designed custom scaffolding solutions. These solutions provided the necessary support throughout the construction phase.

Challenges Overcome

Scaffolding in Saudi Arabia faces unique challenges. The harsh desert climate is one of the most significant obstacles. High temperatures and sandstorms can affect the stability of scaffolding. Engineers use corrosion-resistant materials to combat this. Regular inspections and maintenance are also crucial.

Another challenge is the complexity of modern architectural designs. Many buildings in Saudi Arabia feature intricate and unconventional shapes. This requires innovative scaffolding solutions. Engineers must adapt and innovate constantly. They often develop custom designs to meet specific project needs.

Safety is always a priority. Strict regulations ensure that scaffolding remains secure. Workers receive extensive training. They follow rigorous safety protocols to prevent accidents. These measures help maintain scaffolding stability throughout the construction process.

Regulations And Standards

Ensuring scaffolding stays up in Saudi Arabia requires strict adherence to regulations and standards. These guidelines ensure safety and stability. Various codes and international standards guide the construction and maintenance of scaffolding. This is crucial for both worker safety and public security.

Local Building Codes

Saudi Arabia follows specific local building codes for scaffolding. These codes outline the requirements for materials, assembly, and maintenance. They mandate regular inspections and certifications. This guarantees that scaffolding structures remain safe and reliable.

- Material quality checks

- Structural stability assessments

- Regular maintenance schedules

Adhering to these codes ensures that scaffolding can withstand local weather conditions. It also helps in preventing accidents and ensuring worker safety.

International Guidelines

Besides local codes, Saudi Arabia also adheres to international guidelines. These guidelines include standards from organizations like OSHA and ISO. They provide a framework for safe scaffolding practices worldwide.

- OSHA Standards

- ISO 9001

- ISO 45001

These international standards ensure that Saudi scaffolding practices align with global safety measures. They cover various aspects, including:

| Aspect | Description |

|---|---|

| Load Capacity | Ensuring scaffolding can support the intended load. |

| Safety Measures | Including guardrails, toeboards, and fall protection. |

| Inspection Protocols | Regular checks to ensure ongoing stability and safety. |

Following both local and international standards is essential. It ensures the safety and stability of scaffolding in Saudi Arabia.

Credit: aaitscaffold.com

Future Of Scaffolding In Saudi Arabia

The future of scaffolding in Saudi Arabia looks promising with emerging technologies and a focus on sustainability. This industry is evolving rapidly to meet modern construction demands. Let’s dive into the exciting advancements shaping the future of scaffolding in Saudi Arabia.

Technological Advancements

Technological advancements are transforming the scaffolding industry in Saudi Arabia. Cutting-edge tools and software are making the scaffolding process more efficient and safer. Here are some key advancements:

- 3D Modeling: Engineers use 3D models to plan scaffolding structures accurately.

- Automation: Automated systems help in the quick assembly and disassembly of scaffolding.

- Smart Sensors: Sensors monitor the stability and safety of scaffolding in real-time.

These technologies ensure precise construction and reduce the risk of accidents.

Sustainability Efforts

Sustainability is a major focus in Saudi Arabia’s scaffolding industry. Companies are adopting eco-friendly practices to reduce their environmental impact.

- Recyclable Materials: Using materials that can be recycled helps in minimizing waste.

- Energy-efficient Processes: Implementing processes that consume less energy to conserve resources.

- Waste Reduction: Strategies to reduce waste during scaffolding construction and dismantling.

These efforts contribute to a greener and more sustainable future for the scaffolding industry in Saudi Arabia.

In conclusion, the scaffolding industry in Saudi Arabia is embracing technological advancements and sustainability efforts. These changes are paving the way for safer and more efficient construction practices.

Frequently Asked Questions

How Is Scaffolding Secured In Saudi Arabia?

Scaffolding in Saudi Arabia is secured using robust frameworks, anchorage, and regular safety inspections. It complies with local regulations and standards. Workers ensure stability by following strict safety protocols.

What Materials Are Used In Saudi Scaffolding?

Scaffolding in Saudi Arabia typically uses steel, aluminum, and sometimes bamboo. These materials provide strength and durability. They are chosen based on the project’s requirements and safety standards.

Are There Specific Regulations For Scaffolding In Saudi Arabia?

Yes, Saudi Arabia has specific regulations for scaffolding. These include safety standards, regular inspections, and worker training. Compliance ensures the scaffolding’s stability and the workers’ safety.

How Often Is Scaffolding Inspected In Saudi Arabia?

Scaffolding in Saudi Arabia is inspected regularly. Inspections occur before use, during use, and after major alterations. Regular inspections ensure safety and stability.

Conclusion

Scaffolding in Saudi Arabia stays up due to strict safety standards. Skilled workers follow precise guidelines. Regular inspections ensure stability. High-quality materials add strength. Proper training is crucial for everyone involved. Weather conditions are always considered. Advanced technologies assist in monitoring.

Safety is the top priority. This ensures projects are completed safely and efficiently. Understanding these factors can help appreciate the process. Scaffolding is essential for construction success.