Scaffolds are essential in construction, but their weight capacity varies. In Saudi Arabia, understanding scaffold strength is crucial for safety.

Scaffolding is a common sight on construction sites across Saudi Arabia. But have you ever wondered how much weight these structures can actually hold? Knowing the load-bearing capacity of scaffolds is essential for ensuring the safety of workers and the integrity of the construction project.

This blog post will explore the factors that determine scaffold strength, the regulations in Saudi Arabia, and best practices for using scaffolds safely. Whether you are a construction professional or just curious, this information is vital. Let’s dive into the details of scaffold weight capacity in Saudi Arabia.

Scaffold Load Capacity Basics

Understanding scaffold load capacity basics is essential for any construction project. Scaffoldings provide a safe platform for workers to perform their tasks. Knowing how much weight a scaffold can hold ensures safety and efficiency. In Saudi Arabia, the standards and regulations may vary. However, the principles of scaffold load capacity remain the same.

Weight Limits

Weight limits refer to the maximum load a scaffold can support. This includes the weight of workers, tools, and materials. Exceeding these limits can lead to accidents and structural failure. It’s important to calculate the total load before use. Always consider the weight of all elements on the scaffold.

Importance Of Load Ratings

Load ratings indicate the maximum weight a scaffold component can bear. They ensure that each part of the scaffold can handle the expected load. Using components without proper load ratings can lead to dangerous situations. Always check load ratings before assembling the scaffold.

Credit: www.facebook.com

Regulations In Saudi Arabia

Understanding the scaffold regulations in Saudi Arabia is crucial for construction projects. The Saudi government has set rules to ensure safety and efficiency. These regulations are designed to protect workers and maintain high standards in the industry.

Local Safety Standards

Saudi Arabia follows strict local safety standards for scaffolding. The Saudi Building Code (SBC) is a key reference. It includes detailed guidelines about scaffold construction and usage.

Key points from the SBC include:

- Scaffolds must be able to support at least four times the maximum intended load.

- Regular inspections are mandatory to ensure scaffolds are safe to use.

- Proper training for workers who will erect, dismantle, or work on scaffolds.

Compliance Requirements

Compliance with scaffold regulations is non-negotiable in Saudi Arabia. Companies must adhere to these rules to avoid fines and ensure worker safety. Here are the main compliance requirements:

- Submit scaffold design plans for approval.

- Conduct regular safety audits.

- Keep detailed records of inspections and maintenance.

Ensuring compliance helps in preventing accidents and maintaining a safe work environment.

Types Of Scaffolds

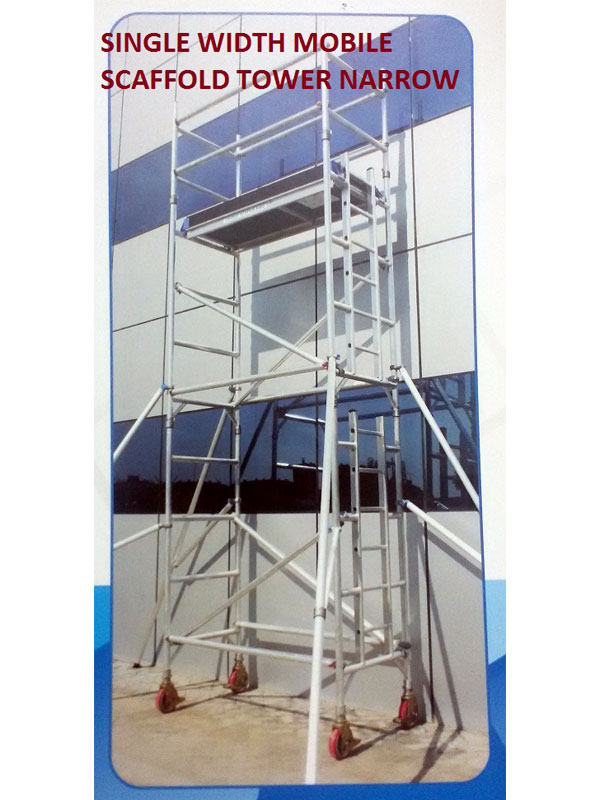

Understanding the types of scaffolds is crucial for ensuring safety and efficiency. Different scaffolds suit various construction needs. In Saudi Arabia, selecting the right scaffold helps manage weight and load capacity effectively.

Supported Scaffolds

Supported scaffolds are the most common type. They consist of one or more platforms held up by rigid supports. These supports can be made from poles, legs, frames, or outriggers. Supported scaffolds are ideal for jobs requiring stability. They can hold a substantial amount of weight. The load capacity depends on the material and design. It’s essential to follow safety standards to prevent accidents.

Suspended Scaffolds

Suspended scaffolds hang from above using ropes or other non-rigid means. Workers use suspended scaffolds for tasks on tall buildings. These scaffolds can be raised or lowered as needed. Although they offer flexibility, they require careful setup. The weight they hold depends on the suspension system. Regular inspection is vital to ensure safety. Always adhere to load limits to avoid mishaps.

Materials Used

When it comes to scaffolding, the materials used play a crucial role in determining its strength and stability. The choice of material impacts how much weight a scaffold can hold. In Saudi Arabia, two common materials for scaffolds are steel and aluminum.

Steel Scaffolds

Steel scaffolds are known for their strength and durability. They can hold heavy loads without bending or breaking. This makes them ideal for large construction projects. Steel scaffolds resist harsh weather conditions. In Saudi Arabia, where temperatures can soar, this is a significant advantage. Steel scaffolds also have a long lifespan. They can be reused multiple times, which makes them cost-effective in the long run.

Aluminum Scaffolds

Aluminum scaffolds are lighter than steel scaffolds. This makes them easier to transport and set up. They are also resistant to corrosion. This is important in areas with high humidity. Aluminum scaffolds are ideal for smaller projects or tasks that need quick assembly. Although they are lighter, they still provide a strong and stable platform. Aluminum scaffolds are perfect for projects that require frequent movement and adjustments.

Factors Affecting Load Capacity

The load capacity of a scaffold in Saudi Arabia depends on various factors. Understanding these factors ensures safety and efficiency in construction projects. Let’s explore two major factors.

Weather Conditions

Weather greatly affects the strength of a scaffold. In Saudi Arabia, extreme heat can weaken scaffold materials. High temperatures may cause metal components to expand. This reduces the overall load capacity. Wind is another weather factor. Strong winds can destabilize the scaffold. This reduces its ability to hold weight. Sandstorms also pose a risk. Sand can accumulate on the scaffold. This adds extra weight and pressure.

Scaffold Design

The design of the scaffold is crucial. Different designs offer different load capacities. A properly designed scaffold distributes weight evenly. This prevents overloading any single part. The type of materials used also matters. Strong materials like steel can hold more weight. Check the connections and joints. They should be secure and tight. Weak joints can reduce the scaffold’s load capacity.

Credit: www.zh-scaffolding.com

Inspection And Maintenance

Inspecting and maintaining scaffolds is crucial for safety. Regular checks help prevent accidents and ensure the scaffold can hold the required weight. In Saudi Arabia, following strict guidelines is necessary to maintain the structural integrity of scaffolds.

Regular Checks

Regular checks are essential. Inspect the scaffold before every use. Look for signs of wear and tear. Ensure all parts are in good condition.

Check the following:

- Joints and connections: Ensure they are secure and not loose.

- Planks and platforms: Check for cracks or splits.

- Supports and braces: Verify they are properly placed and undamaged.

Regular checks help identify potential issues early. This prevents accidents and extends the life of the scaffold.

Common Defects

Identifying common defects is crucial for scaffold safety. Some defects are more prevalent and can pose serious risks.

| Defect | Description | Action |

|---|---|---|

| Corrosion | Rust on metal parts. | Clean and replace if necessary. |

| Cracks | Visible splits in planks. | Replace damaged planks. |

| Loose fittings | Joints and connections not tight. | Tighten or replace fittings. |

Addressing these defects promptly is vital. It ensures the scaffold remains safe and functional.

Training And Certification

Scaffolds in Saudi Arabia are built to hold significant weight, ensuring safety. Training and certification help determine exact load capacities, ensuring compliance with safety standards.

Ensuring the safety of scaffolding in Saudi Arabia is crucial. Proper training and certification play a key role. Workers must be knowledgeable and competent. This guarantees that scaffolding can hold the required weight safely.Worker Training Programs

Worker training programs are essential. They teach employees how to set up and use scaffolding correctly. These programs cover various safety protocols and best practices. Workers learn about load limits and weight distribution. This helps prevent accidents and ensures stability. Training programs often include hands-on practice. Workers get real-life experience under supervision. This practical approach builds confidence and competence. It also ensures that workers can handle different scenarios.Certification Processes

Certification processes are strict and thorough. Workers must pass written and practical exams. These exams test their knowledge and skills. Passing these tests is mandatory for certification. Certified workers are more reliable. They understand the risks and safety measures. Certification ensures that scaffolding can hold the required weight. It also boosts overall safety on construction sites. Employers in Saudi Arabia value certified workers. They know these workers have undergone rigorous training. This reduces the risk of accidents and enhances productivity. Certified workers are a valuable asset to any construction team. “`Accident Prevention Tips

Accident prevention on scaffolds is crucial for worker safety. Knowing how much weight a scaffold can hold in Saudi Arabia is essential. But, understanding the weight limit alone isn’t enough. Following proper guidelines and emergency procedures helps prevent accidents.

Proper Use Guidelines

Ensure the scaffold is erected on a stable surface. Avoid overloading it with materials or workers. Each scaffold has a specific weight capacity. Respect this limit to avoid collapse. Regularly inspect the scaffold for any damage. Fix issues before use. Only trained workers should assemble and disassemble scaffolds. Use guardrails and toe boards to prevent falls. Keep the scaffold free of unnecessary objects. This reduces tripping hazards.

Emergency Procedures

Always have an emergency plan ready. Train workers on what to do in case of scaffold failure. Keep first-aid kits easily accessible. Ensure that all workers know the location. Have a clear communication system for emergencies. This could be radios or a whistle system. Conduct regular emergency drills. This ensures everyone knows their role. Make sure to have contact numbers for emergency services. Display these numbers prominently at the site.

Credit: www.amazon.sa

Frequently Asked Questions

How Much Weight Can A Scaffold Hold?

The weight a scaffold can hold depends on its design and construction. Generally, scaffolds in Saudi Arabia can support between 1,000 to 4,000 pounds. Always check the manufacturer’s specifications for exact weight limits.

Are There Regulations For Scaffold Weight Limits In Saudi Arabia?

Yes, Saudi Arabia follows strict regulations for scaffold weight limits. These regulations ensure safety and compliance with international standards. Always adhere to these guidelines to avoid accidents and legal issues.

What Factors Affect Scaffold Weight Capacity?

Several factors affect scaffold weight capacity. These include the type of materials used, the design, and construction quality. Environmental conditions and load distribution also play a crucial role.

How To Ensure Scaffold Safety In Saudi Arabia?

To ensure scaffold safety, always follow manufacturer guidelines. Regularly inspect the scaffold for any damages. Ensure proper training for workers and adhere to local regulations.

Conclusion

Scaffold safety is crucial in Saudi Arabia’s construction industry. Knowing weight limits ensures safe operations. Always check the scaffold’s capacity before use. Follow local regulations and guidelines to maintain safety. Regular inspections help identify potential issues early. Proper training for workers is essential.

Safe scaffolding practices protect lives and assets. Stay informed, stay safe.