Scaffolding measurement in Saudi Arabia follows strict guidelines. Accurate measurement ensures safety and compliance.

Understanding scaffolding measurement is crucial for construction projects. In Saudi Arabia, specific standards and practices are in place. These standards guarantee worker safety and structural integrity. Knowing how scaffolding is measured helps in planning and execution. It ensures that all structures meet legal requirements.

This blog explores the methods used in Saudi Arabia. We will cover the key aspects of scaffolding measurement. Learn why these standards are vital for any construction project. Discover the steps involved in measuring scaffolding accurately.

Introduction To Scaffolding Measurement

Scaffolding measurement is a vital process in the construction industry. Accurate measurements ensure safety and efficiency. In Saudi Arabia, specific guidelines and standards govern this process.

Importance Of Accurate Measurement

Accurate measurement of scaffolding impacts several critical factors:

- Safety: Proper measurements prevent accidents and ensure worker safety.

- Cost-efficiency: Minimizes material wastage and reduces project costs.

- Compliance: Ensures adherence to local regulations and standards.

Measurement errors can lead to significant risks. Thus, precision is key.

Overview Of Scaffolding In Saudi Arabia

Scaffolding in Saudi Arabia follows stringent standards. These standards ensure the safety of construction sites.

Common types of scaffolding include:

- Supported Scaffolding: Built from the ground up.

- Suspended Scaffolding: Hung from above.

- Rolling Scaffolding: Equipped with wheels for mobility.

| Type | Usage | Advantages |

|---|---|---|

| Supported | General construction | Stable and versatile |

| Suspended | High-rise buildings | Reaches high areas |

| Rolling | Indoor projects | Easy to move |

Saudi Arabia’s guidelines ensure scaffolding is safe and reliable. These guidelines are essential for the success of construction projects.

Credit: www.perihk.com

Saudi Arabian Scaffolding Standards

Scaffolding plays a crucial role in the construction industry. In Saudi Arabia, specific standards ensure safety and efficiency in scaffolding practices. Understanding these standards is essential for compliance and successful project execution.

Regulatory Bodies

Several regulatory bodies oversee scaffolding standards in Saudi Arabia. The Saudi Standards, Metrology and Quality Organization (SASO) is a key player. SASO sets the guidelines for construction materials and practices. Another important body is the Ministry of Municipal and Rural Affairs (MOMRA). MOMRA ensures that building codes and safety regulations are followed. These organizations work together to maintain high safety standards.

Key Standards And Regulations

Saudi Arabian scaffolding standards are detailed and specific. SASO provides guidelines on materials, design, and construction techniques. Scaffolding must be strong, stable, and capable of supporting its weight. Regular inspections are mandatory. Workers must be trained and equipped with safety gear. Safety nets and guardrails are essential to prevent falls. These regulations aim to reduce accidents and enhance worker safety.

Types Of Scaffolding Used

In Saudi Arabia, scaffolding is crucial for construction. It ensures safety and efficiency. Different types of scaffolding are used based on the project’s needs. This section discusses common types and their material specifications.

Common Scaffolding Types

There are several common types of scaffolding used in Saudi Arabia:

- Tube and Coupler Scaffolding: This type is versatile and flexible. It involves tubes connected by couplers. It’s suitable for complex structures.

- System Scaffolding: This includes modular components. It’s quick to assemble. Types include Cuplock, Kwikstage, and Haki.

- Frame Scaffolding: Popular for residential projects. It’s easy to set up. It consists of welded frames.

- Suspended Scaffolding: Used for high-rise buildings. It’s hung from the roof. Workers can adjust its height.

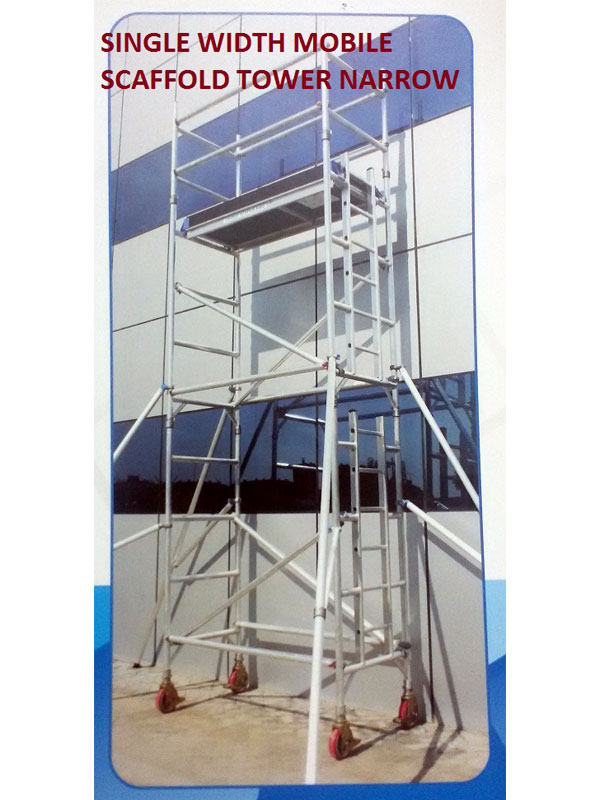

- Mobile Scaffolding: This type has wheels. It’s easy to move. Ideal for tasks requiring frequent repositioning.

Material Specifications

Scaffolding materials must meet specific standards. This ensures safety and durability. Common materials include:

- Steel: Strong and durable. Resistant to weather conditions. Heavy but provides excellent support.

- Aluminum: Lightweight and easy to handle. Not as strong as steel. Suitable for smaller projects.

- Wood: Traditional material. Used for temporary or short-term scaffolding. Less common in modern construction.

Let’s explore the material requirements in detail:

| Material | Characteristics | Usage |

|---|---|---|

| Steel | Strong, durable, weather-resistant | Large-scale projects, high-rise buildings |

| Aluminum | Lightweight, easy to handle | Small to medium projects, mobile scaffolding |

| Wood | Traditional, less durable | Short-term, temporary scaffolding |

Each material has its pros and cons. The choice depends on the project’s needs. Always prioritize safety and compliance with regulations.

Measurement Techniques

Scaffolding measurement is crucial in construction projects. It ensures safety, compliance, and efficiency. In Saudi Arabia, various techniques are employed to achieve accurate results. This section explores both traditional and modern methods used for scaffolding measurement.

Traditional Methods

Traditional methods have been in use for many years. They are trusted for their simplicity and reliability.

- Manual Measurement: Using rulers and tape measures to record dimensions. This method requires skilled workers.

- Plumb Bob: Ensures vertical alignment. It is simple but effective.

- Spirit Level: Checks horizontal levels. It is crucial for scaffold stability.

These methods are cost-effective. Yet, they can be time-consuming and prone to human error.

Modern Technologies

Advancements in technology have introduced new measurement techniques. They enhance accuracy and efficiency.

- Laser Scanning: Provides precise measurements using laser beams. It is fast and highly accurate.

- Drones: Capture aerial views and measurements. They are useful for large-scale projects.

- 3D Modeling: Creates detailed digital models of the scaffolding. It helps in planning and verification.

These technologies reduce the margin of error. They also save time and improve safety standards.

Below is a comparison table of traditional methods and modern technologies:

| Method | Accuracy | Time Efficiency | Cost |

|---|---|---|---|

| Manual Measurement | Moderate | Low | Low |

| Laser Scanning | High | High | High |

| Drones | High | High | Moderate |

Combining both methods can yield optimal results. It balances cost, accuracy, and time efficiency.

Safety Considerations

Ensuring safety in scaffolding operations in Saudi Arabia is paramount. Proper safety considerations help prevent accidents and ensure compliance with regulations. Below, we delve into the critical aspects of safety considerations, focusing on risk assessment and safety protocols.

Risk Assessment

A thorough risk assessment is essential before scaffolding work begins. This process involves identifying potential hazards and evaluating the risks associated with each.

- Identify Hazards: Check for electrical wires, unstable ground, and weather conditions.

- Evaluate Risks: Determine the likelihood and severity of each identified hazard.

- Control Measures: Implement strategies to mitigate risks, such as securing the base of the scaffold.

Regular risk assessments ensure updated safety measures, adapting to changing conditions.

Safety Protocols

Implementing strict safety protocols is crucial to protect workers and bystanders. Here are some standard protocols:

- Training: Ensure all workers receive proper training on scaffold use and safety measures.

- Inspections: Conduct regular inspections of scaffolding for stability and safety.

- Personal Protective Equipment (PPE): Workers should wear helmets, harnesses, and non-slip footwear.

- Signage: Use clear signs to warn of potential hazards and restricted areas.

Adhering to these safety protocols helps prevent accidents and ensures a safe working environment.

| Protocol | Description |

|---|---|

| Training | Proper training for all workers on scaffold safety. |

| Inspections | Regular checks of scaffolding for stability. |

| PPE | Use of helmets, harnesses, and non-slip footwear. |

| Signage | Clear signs to indicate hazards and restricted areas. |

Training And Certification

Scaffolding is crucial in construction, ensuring safety and efficiency. In Saudi Arabia, the importance of proper training and certification for scaffolding cannot be overstated. This section delves into the necessary certifications and available training programs in the region.

Required Certifications

In Saudi Arabia, scaffolding workers need specific certifications. These certifications ensure workers know safety standards and best practices. The Saudi Council of Engineers (SCE) mandates these certifications.

Workers must pass exams to get certified. These exams test their knowledge of scaffolding techniques. They also test their understanding of safety procedures.

Employers prefer certified workers. Certification proves a worker’s competence. It also ensures the worker can handle scaffolding tasks safely.

Training Programs

Several training programs are available in Saudi Arabia. These programs help workers prepare for certification exams. The programs cover essential topics.

Topics include scaffold erection and dismantling. Safety procedures are also a key focus. Training programs often involve hands-on practice.

Institutions like the Saudi Council of Engineers offer these programs. Private training centers also provide courses. Both options ensure workers get the skills they need.

Training programs are essential for scaffolding workers. They ensure workers are well-prepared. This preparation helps in maintaining safety standards on construction sites.

Challenges In Measurement

Measuring scaffolding in Saudi Arabia presents unique challenges. Accurate measurement is crucial for safety and compliance. These challenges can affect the efficiency and safety of construction projects.

Common Issues

Several common issues arise in scaffolding measurement:

- Environmental factors: Harsh weather conditions can affect measurements.

- Human error: Inaccurate data entry can lead to mistakes.

- Equipment limitations: Outdated tools may provide unreliable readings.

- Regulatory compliance: Ensuring adherence to local regulations can be complex.

Solutions And Best Practices

Implementing effective solutions and best practices can address these issues:

- Use advanced tools: Modern measurement tools provide more accurate readings.

- Training programs: Regular training ensures workers understand measurement techniques.

- Regular maintenance: Keep equipment in good condition to avoid errors.

- Compliance checks: Regularly review and update practices to align with regulations.

These measures can improve the accuracy and reliability of scaffolding measurements. Ensuring safety and efficiency on construction sites.

Credit: www.indexbox.io

Future Of Scaffolding Measurement

The future of scaffolding measurement in Saudi Arabia is evolving rapidly. Emerging trends and technological advancements are shaping the industry. This transformation promises greater accuracy, efficiency, and safety.

Emerging Trends

Emerging trends in scaffolding measurement focus on precision. Digital tools are becoming more common. They help in better planning and resource management. These tools ensure scaffolding structures meet safety standards. Companies are investing in training for their staff. This ensures proper use of new measurement technologies.

Technological Advancements

Technological advancements play a significant role. Laser scanning technology is one example. It provides accurate measurements in less time. Drones are also being used for inspections. They offer a bird’s-eye view of scaffolding structures. This helps in identifying potential issues quickly. 3D modeling software is another advancement. It allows for detailed planning and visualization. These technologies make scaffolding measurement more efficient and reliable.

Credit: www.perihk.com

Frequently Asked Questions

How Is Scaffolding Measurement Done In Saudi Arabia?

Scaffolding measurement in Saudi Arabia follows strict safety standards. Measurements include height, width, and load capacity. Compliance with local regulations is essential.

What Standards Are Used For Scaffolding In Saudi Arabia?

Saudi Arabia uses international standards like ISO and OSHA. Local guidelines must also be followed. These ensure safety and quality.

Are There Specific Tools For Scaffolding Measurement?

Yes, specific tools include measuring tapes, levels, and plumb lines. These tools ensure accurate and safe scaffolding structures.

Do Scaffolding Measurements Affect Project Timelines?

Accurate measurements ensure timely project completion. Incorrect measurements can lead to delays. Proper planning and measurement are crucial.

Conclusion

Measuring scaffolding in Saudi Arabia ensures safety and efficiency in construction. Accurate measurement helps avoid accidents and meets regulatory standards. Workers and managers benefit from understanding the process. Proper scaffolding measurement supports smooth project progress. Always follow local guidelines and use reliable tools.

This practice guarantees safer work environments for everyone involved.