Designing scaffolding in Saudi Arabia requires attention to safety and local regulations. It’s essential to understand the climate and construction standards.

In Saudi Arabia, scaffolding is crucial for many construction projects. The extreme weather conditions and unique architectural styles demand careful planning. Proper scaffolding ensures worker safety and project efficiency. Understanding the local guidelines and standards is key. This blog will guide you through the essential steps for designing scaffolding in Saudi Arabia.

From choosing materials to following safety protocols, we’ll cover everything you need to know. Whether you’re a contractor or an engineer, this guide will help you navigate the complexities of scaffolding design in this region. Let’s dive into the essentials and ensure your projects run smoothly and safely.

Introduction To Scaffolding Design

Scaffolding is an essential part of construction projects. It provides a safe platform for workers. Designing scaffolding correctly ensures safety and efficiency. In Saudi Arabia, construction projects are on the rise. Understanding scaffolding design is crucial for these projects.

Importance Of Proper Design

Proper scaffolding design is vital. It ensures the safety of workers. A well-designed scaffold prevents accidents. It also increases productivity. Here are some key points to consider:

- Safety: Reduces the risk of falls and injuries.

- Stability: Ensures the scaffold can support weight.

- Compliance: Meets local regulations and standards.

Overview Of Saudi Arabia’s Construction Environment

Saudi Arabia’s construction sector is growing rapidly. The climate is hot and dry. This affects scaffolding materials. Projects range from skyscrapers to residential buildings. Understanding the environment helps in designing suitable scaffolding.

Here is a quick overview of the construction environment:

| Factor | Impact on Scaffolding |

|---|---|

| Climate | Heat affects material strength and durability. |

| Project Scale | Large projects require more robust scaffolding. |

| Regulations | Must comply with local safety standards. |

Regulatory Standards

Designing scaffolding in Saudi Arabia requires strict adherence to regulatory standards. These standards ensure safety and compliance for construction projects. Understanding these regulations is crucial for successful scaffolding design.

Saudi Building Code

The Saudi Building Code (SBC) sets the framework for scaffolding design. It outlines specific requirements for materials, dimensions, and load capacities. Compliance with the SBC ensures safety and durability.

Scaffolding must meet these criteria to prevent accidents. The code also includes guidelines for inspection and maintenance. Regular checks are mandatory to ensure scaffolding remains safe.

International Standards

Saudi Arabia also aligns with international standards for scaffolding. These include guidelines from organizations like ISO and OSHA. These standards provide a global benchmark for safety and quality.

Using international standards helps maintain consistency. It ensures that scaffolding is reliable and robust. This is especially important for projects involving international teams.

Adhering to both local and international standards guarantees the highest safety levels. It minimizes risks and promotes efficient construction processes.

Material Selection

Choosing the right materials for scaffolding is crucial in Saudi Arabia. The climate, safety standards, and project requirements all play a role. This section will guide you through the best practices for selecting materials.

Types Of Materials

Scaffolding materials vary. Each has its pros and cons. The common types include:

- Steel: Strong and durable but heavy.

- Aluminum: Lightweight and corrosion-resistant.

- Wood: Traditional but less durable.

Durability And Safety Considerations

Durability and safety are paramount in scaffolding design. Here are some key points:

| Material | Durability | Safety |

|---|---|---|

| Steel | Very high | Excellent for heavy loads |

| Aluminum | High | Good for lightweight structures |

| Wood | Moderate | Good for short-term projects |

Steel scaffolding is ideal for long-term projects. It can bear heavy loads. Aluminum is best for projects requiring easy transport. Its lightweight nature makes it easy to handle. Wood is suitable for short-term tasks. It is less durable but cost-effective.

Credit: www.altrad.com

Load Capacity And Stability

Designing scaffolding in Saudi Arabia requires understanding load capacity and stability. These factors ensure the safety and efficiency of scaffolding structures. Careful calculations and proper materials are key to a successful design.

Calculating Load Capacity

Calculating the load capacity of scaffolding involves knowing the weight it will support. This includes workers, tools, and materials. Here’s a simple guide:

- Estimate the total weight of workers.

- Add the weight of tools and equipment.

- Include the weight of materials stored on the scaffold.

- Apply a safety factor, typically 4:1, for additional safety.

| Component | Weight (kg) |

|---|---|

| Workers | 300 |

| Tools | 100 |

| Materials | 200 |

| Total | 600 |

| Safety Factor (4:1) | 2400 |

This table shows an example calculation. The total load capacity needed is 2400 kg. This ensures the scaffolding can handle the expected weight safely.

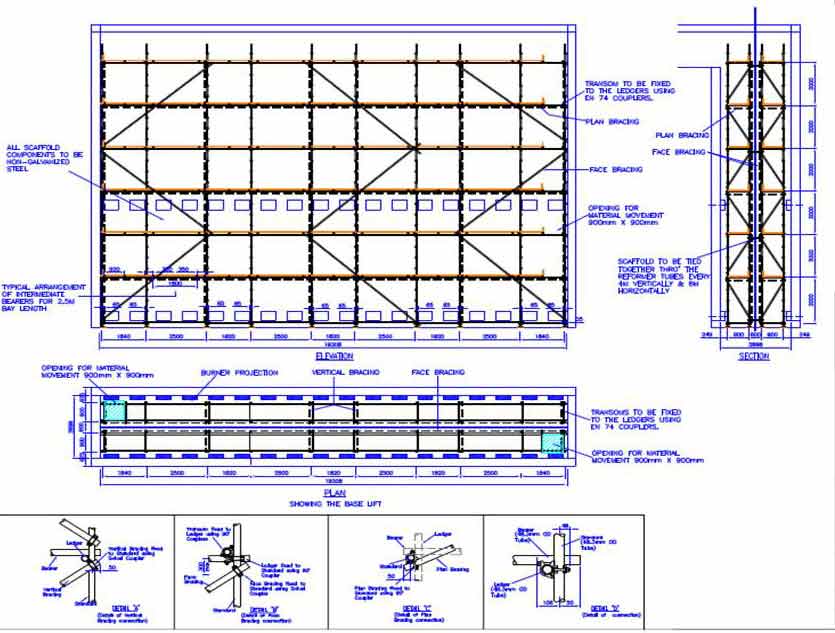

Ensuring Stability

Ensuring stability is crucial for safe scaffolding. Stability prevents accidents and ensures a solid working platform. Consider these factors:

- Base Width: A wide base provides better support.

- Bracing: Use diagonal bracing for added strength.

- Ground Conditions: Place scaffolding on solid, level ground.

- Anchoring: Secure scaffolding to nearby structures if possible.

These steps help maintain a stable structure. Stability is essential for worker safety and project success.

Erection And Dismantling Procedures

Designing scaffolding in Saudi Arabia involves crucial steps for safe erection and dismantling. Proper procedures ensure the safety of workers and the stability of the structure. Understanding these procedures is vital for any construction project.

Safe Erection Practices

Plan the erection process carefully. Check the site for hazards. Use stable ground for the base. Ensure all components are in good condition. Follow the manufacturer’s instructions. Train workers on safety protocols. Always use personal protective equipment (PPE). Secure all connections firmly. Inspect the scaffolding regularly during erection.

Proper Dismantling Techniques

Begin dismantling from the top. Remove components in reverse order of erection. Ensure a clear area around the scaffolding. Use proper tools and safety gear. Lower materials carefully to the ground. Avoid dropping or throwing components. Inspect each part for damage. Store components properly for future use.

Safety Measures

Designing scaffolding in Saudi Arabia involves rigorous safety measures. These measures ensure both the workers’ safety and the structure’s integrity. Here are some essential safety protocols to follow:

Personal Protective Equipment

Workers must use personal protective equipment (PPE) at all times. This includes:

- Helmets

- Safety goggles

- Gloves

- High-visibility vests

- Non-slip footwear

- Harnesses

Helmets protect against falling objects. Safety goggles shield the eyes from dust and debris. Gloves ensure a firm grip while handling materials. High-visibility vests make workers easily noticeable. Non-slip footwear prevents slips and falls. Harnesses are crucial when working at heights.

Emergency Protocols

Having clear emergency protocols is vital. Workers must know what to do in an emergency. Some key protocols include:

- Evacuation routes and procedures

- Location of first aid kits

- Emergency contact numbers

- Firefighting equipment locations

Evacuation routes should be clearly marked. First aid kits must be easily accessible. Emergency contact numbers should be posted in visible areas. Firefighting equipment, like extinguishers, should be within reach.

Training sessions should be held regularly. Workers must practice these protocols to ensure they are well-prepared.

| Safety Measure | Details |

|---|---|

| Personal Protective Equipment | Helmets, goggles, gloves, vests, footwear, harnesses |

| Emergency Protocols | Evacuation routes, first aid kits, contact numbers, firefighting equipment |

Implementing these safety measures can greatly reduce risks. They help create a secure working environment on scaffolding sites in Saudi Arabia.

Training And Certification

Designing scaffolding in Saudi Arabia requires proper training and certification. Workers must be skilled and knowledgeable to ensure safety and compliance. This section will cover the essential training programs and certification requirements for scaffolding professionals.

Mandatory Training Programs

In Saudi Arabia, there are several mandatory training programs for scaffolding designers and workers. These programs are designed to provide comprehensive knowledge and practical skills.

- Scaffolding Safety Training: This program focuses on the safe erection, use, and dismantling of scaffolding.

- Advanced Scaffolding Design: This course covers the principles of scaffolding design, including load calculations and structural analysis.

- Risk Assessment and Management: Workers learn to identify potential hazards and implement safety measures.

- First Aid Training: Basic first aid training is essential for all scaffolding workers.

Certification Requirements

Certification is crucial for scaffolding professionals in Saudi Arabia. The following certifications are required:

- Scaffolding Erector Certification: This certification ensures that workers are competent in erecting and dismantling scaffolds safely.

- Scaffolding Supervisor Certification: Supervisors need this certification to oversee scaffolding projects and ensure compliance with safety standards.

- Scaffolding Inspector Certification: Inspectors must be certified to check the integrity and safety of scaffolding structures.

Each certification requires passing a written exam and practical assessment. Continuing education and recertification are often required to stay updated with industry standards and regulations.

| Certification | Required Training |

|---|---|

| Scaffolding Erector | Scaffolding Safety, Risk Assessment |

| Scaffolding Supervisor | Advanced Scaffolding Design, First Aid |

| Scaffolding Inspector | Scaffolding Safety, Risk Assessment |

Maintenance And Inspection

Ensuring the safety and longevity of scaffolding structures in Saudi Arabia requires diligent maintenance and inspection. Regular checks and proper upkeep help prevent accidents and extend the life of the scaffolding. Below, we discuss routine inspections and maintenance best practices for scaffolding in Saudi Arabia.

Routine Inspections

Routine inspections are crucial for identifying potential hazards. They help in maintaining the structural integrity of scaffolding. Inspect scaffolding components daily before use. Look for any signs of wear, damage, or corrosion. Include the following in your routine inspections:

- Check for loose or missing bolts and connections.

- Inspect planks for cracks or splits.

- Ensure guardrails and toe boards are secure.

- Look for rust or corrosion on metal parts.

- Verify that the base plates are stable and level.

Maintenance Best Practices

Effective maintenance practices are key to scaffolding safety. Proper maintenance not only enhances safety but also prolongs the lifespan of the scaffolding. Here are some best practices:

| Maintenance Task | Frequency |

|---|---|

| Cleaning | Weekly |

| Lubricating moving parts | Monthly |

| Replacing damaged components | As needed |

| Checking for rust and corrosion | Monthly |

Follow these practices to maintain scaffolding:

- Regularly clean scaffolding to remove dirt and debris.

- Lubricate moving parts to ensure smooth operation.

- Replace any damaged or worn-out components immediately.

- Apply anti-rust treatment to metal parts monthly.

By adhering to these routine inspections and maintenance best practices, scaffolding in Saudi Arabia can remain safe and functional for extended periods.

Case Studies

Understanding the intricacies of scaffolding design is crucial for ensuring safety and efficiency in construction projects. In Saudi Arabia, several successful projects highlight the best practices and lessons learned. Let’s dive into some case studies to understand these aspects better.

Successful Projects In Saudi Arabia

Saudi Arabia has seen many successful scaffolding projects. These projects have set benchmarks in safety and innovation. Here are a few notable examples:

| Project Name | Location | Key Highlights |

|---|---|---|

| Kingdom Tower | Jeddah | World’s tallest scaffolding structure |

| King Abdulaziz International Airport | Jeddah | Complex scaffolding for a vast area |

| King Salman Park | Riyadh | Innovative modular scaffolding systems |

Kingdom Tower in Jeddah is a prime example. The scaffolding design ensured safety at unprecedented heights. This project required precise engineering and innovative materials.

At the King Abdulaziz International Airport, scaffolding covered a vast area. The project highlighted the importance of planning and coordination. The design allowed for efficient workflow without compromising safety.

King Salman Park in Riyadh used modular scaffolding systems. This approach allowed for flexibility and quick adjustments. The project demonstrated how modular systems can save time and costs.

Lessons Learned

Each project offers valuable lessons. Here are some key takeaways:

- Safety First: Always prioritize safety in design. Implement regular inspections.

- Planning: Detailed planning prevents delays. It ensures efficient workflows.

- Material Quality: Use high-quality materials. This ensures durability and safety.

- Flexibility: Design should allow for adjustments. This helps in managing unexpected changes.

These lessons emphasize the importance of safety, planning, and quality. They show how successful scaffolding projects can be achieved. These insights are crucial for future projects in Saudi Arabia.

Credit: m.facebook.com

Future Trends

As Saudi Arabia continues to grow and develop, the construction industry is seeing rapid changes. Scaffolding, a crucial part of this industry, is also evolving. Future trends in scaffolding design are focusing on innovations and sustainability. These trends aim to improve safety, efficiency, and environmental impact.

Innovations In Scaffolding Design

Technological advancements are driving new innovations in scaffolding design. One major trend is the use of lightweight materials. These materials are easier to handle and reduce transportation costs. Another trend is modular scaffolding systems. These systems allow for quick assembly and disassembly. They also offer greater flexibility in design.

Digital tools are playing a big role too. Scaffolding design software helps to create precise plans. This reduces errors and improves safety. Drones are being used for inspections. They provide real-time data and can reach hard-to-access areas. These innovations are making scaffolding more efficient and safer.

Sustainable Practices

Sustainability is becoming a key focus in scaffolding design. Using eco-friendly materials is one way to achieve this. Recycled aluminum and steel are popular choices. They reduce the environmental impact without compromising strength and durability.

Energy-efficient processes are also being adopted. For example, using solar-powered equipment on construction sites. Waste reduction is another important practice. Modular scaffolding systems produce less waste. They can be reused for multiple projects. These sustainable practices are not only good for the environment but also cost-effective.

Credit: m.facebook.com

Frequently Asked Questions

What Are The Key Considerations For Scaffolding Design?

Key considerations include load capacity, stability, and worker safety. Ensure compliance with local regulations and standards.

How To Ensure Scaffolding Safety In Saudi Arabia?

Regular inspections, proper installation, and using quality materials ensure scaffolding safety. Training workers is also essential.

What Materials Are Best For Scaffolding?

Steel and aluminum are commonly used. They are durable, strong, and provide stability for scaffolding structures.

Are There Specific Regulations For Scaffolding In Saudi Arabia?

Yes, Saudi Arabia has specific regulations. Compliance with these regulations ensures safety and legal adherence.

Conclusion

Designing scaffolding in Saudi Arabia requires careful planning and attention to detail. Safety standards must be met to ensure worker protection. Use quality materials and follow local regulations. Regular inspections help maintain scaffold integrity. Proper training for workers is essential for safe operations.

With these steps, you can create effective and safe scaffolding structures. Stay informed and prioritize safety in every project.