Inspecting scaffolding is crucial for construction safety. In Saudi Arabia, it’s essential to follow specific guidelines.

Scaffolding in construction helps workers reach high places. It must be safe and stable. Saudi Arabia has strict rules for scaffolding inspections. These rules ensure the safety of workers and the public. Knowing how to inspect scaffolding properly is vital.

This guide will explain the steps and checks needed for a thorough inspection. Whether you are a site manager, worker, or safety officer, understanding these steps can prevent accidents and save lives. Let’s dive into the essentials of scaffolding inspection in Saudi Arabia.

Introduction To Scaffolding Inspection

Scaffolding is vital in construction, especially in Saudi Arabia’s growing industry. Inspecting scaffolding ensures safety for workers and passersby. A thorough inspection reduces risks and prevents accidents. Understanding the inspection process is crucial for all involved.

Importance Of Scaffolding Safety

Scaffolding safety cannot be overlooked. Many construction accidents involve scaffolding. Proper inspection saves lives and money. It also ensures compliance with legal standards. Safe scaffolding boosts worker confidence. Confident workers are more productive and efficient.

Overview Of Saudi Arabian Standards

Saudi Arabia follows strict scaffolding standards. The Saudi Standards, Metrology, and Quality Organization (SASO) sets these guidelines. These standards ensure scaffolding stability and safety. Regular inspections must meet these standards. Failing to comply can lead to severe penalties. Adhering to these standards protects workers and the public.

Credit: www.facebook.com

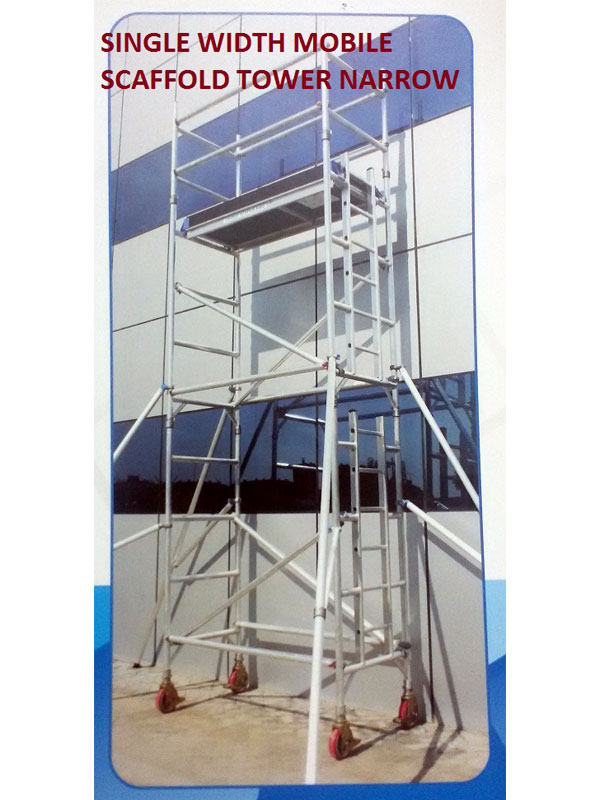

Types Of Scaffolding

Inspecting scaffolding in Saudi Arabia involves checking various types like single, double, and cantilever scaffolds. Ensure all parts are secure and stable. Regular inspections guarantee worker safety on construction sites.

Inspecting scaffolding in construction is crucial for ensuring safety and efficiency, especially in places like Saudi Arabia where the construction industry is booming. Understanding the types of scaffolding is the first step to ensuring that your structures are stable and secure. Different types of scaffolding offer distinct advantages and are suited for various construction needs. Let’s explore some common types of scaffolding you might encounter on a construction site.Supported Scaffolds

Supported scaffolds are the most common type you’ll see on construction sites. They are built from the ground up, providing a solid base with vertical and horizontal supports. These scaffolds are ideal for tasks that require a sturdy platform, such as bricklaying or plastering. Imagine you’re working on a high-rise building. Supported scaffolds give you the confidence to move materials and tools without worrying about stability. However, always ensure the base is level and the structure is properly braced to prevent accidents.Suspended Scaffolds

Suspended scaffolds hang from the top of a building using ropes or other non-rigid supports. These are perfect for projects like window washing or painting skyscrapers. They allow workers to access hard-to-reach areas with ease. Working on a suspended scaffold might feel like an adventure, but it demands caution. Ensure all ropes and pulleys are inspected regularly for wear and tear. Your safety depends on these components functioning flawlessly.Rolling Scaffolds

Rolling scaffolds are essentially supported scaffolds on wheels. They offer the flexibility to move across a construction site without dismantling the entire structure. This is particularly useful in projects that cover a large area or when tasks need to be performed at various locations. Consider a time when you needed to paint a long corridor. A rolling scaffold would let you glide from one end to the other, saving time and effort. Just be sure to lock the wheels when working to prevent any unwanted movement. Understanding these scaffolding types helps you choose the right one for your project. Each type has its unique benefits and safety considerations. Which type do you think best suits your current construction needs?Pre-inspection Checklist

Inspecting scaffolding in Saudi Arabia requires checking stability, ensuring proper assembly, and confirming safety measures. Examine all components for damage or wear. Verify that the structure is level and grounded.

Inspecting scaffolding in construction is crucial for ensuring the safety and efficiency of your project. A thorough pre-inspection checklist can help you identify potential hazards before they become issues. This checklist not only ensures compliance with local regulations but also protects your workers. Let’s break down the essential steps to make your inspection thorough and effective. ###Documentation Review

Start by reviewing all the necessary documentation. This includes the scaffolding design plan, manufacturer instructions, and any previous inspection reports. Ensure that all documents are up-to-date and relevant to the current project. Check if the scaffolding design meets Saudi Arabian standards and regulations. This is crucial for compliance and safety. Ensure that all workers have received proper training and certification specific to the scaffolding in use. ###Visual Inspection Basics

Conduct a visual inspection of the scaffolding. Look for visible signs of damage or wear, such as rust, cracks, or bent components. These issues can compromise the integrity of the scaffolding and lead to accidents. Ensure that all scaffolding parts are correctly assembled and secured. Loose bolts or missing pins can be dangerous. Check that the base is stable and on firm ground. Uneven surfaces can cause the scaffolding to tilt or collapse. Remember to inspect safety features such as guardrails and toe boards. These components are vital for preventing falls. Make sure they are in place and in good condition. By following these steps, you can help ensure the safety and efficiency of your construction project. Are there other specific challenges you face when inspecting scaffolding? Share your thoughts and let’s discuss solutions.Structural Components

Inspecting scaffolding is critical in Saudi Arabian construction sites. Ensuring safety and stability depends on the structural components. Understanding these elements helps prevent accidents and maintain efficiency.

Base Plates And Mud Sills

Base plates distribute the scaffold’s weight evenly. They must rest on solid ground. Mud sills add stability on softer surfaces. Check for cracks or bends. Ensure they are correctly positioned and level.

Bracing And Ties

Bracing stabilizes the scaffold. It prevents swaying or collapsing. Inspect all bracing connections. Confirm they are tight and secure. Ties anchor the scaffold to structures. Verify their strength and placement. They should hold firm under pressure.

Planks And Decking

Planks provide a working platform. Check for signs of wear or damage. They should be free of cracks or splits. Ensure they are properly supported. Decking must be slip-resistant and stable. Inspect for gaps or loose boards. Safety depends on secure planking.

Safety Features

Safety in scaffolding is crucial in construction. Inspecting scaffolding involves checking key features. These features prevent accidents and ensure worker safety. In Saudi Arabia, construction projects demand strict safety checks. Let’s explore some essential safety features.

Guardrails And Toe Boards

Guardrails protect workers from falling off scaffolding. They must be strong and secure. Inspect guardrails for damage or loose fittings. Toe boards stop tools and materials from slipping off edges. Ensure toe boards are in place and sturdy. Together, they enhance worker safety.

Access And Egress

Safe access and egress are vital. Workers need clear paths to enter and exit scaffolding. Ladders and ramps should be secure and stable. Ensure they meet safety standards. Check that pathways are free from obstructions. Proper access reduces accident risks.

Load Capacity

Scaffolding must support the load it carries. Inspect load ratings before use. Overloading can lead to collapse. Check that materials don’t exceed capacity. Ensure scaffolding components are strong enough. Proper load management is essential for safety.

Common Hazards

Inspecting scaffolding in construction sites in Saudi Arabia is crucial. Common hazards can jeopardize worker safety and project success. Understanding these hazards helps prevent accidents and ensures efficient operation. Let’s explore some frequent risks associated with scaffolding.

Environmental Factors

Environmental conditions impact scaffolding safety. Harsh weather in Saudi Arabia poses challenges. Intense heat can weaken materials, affecting structural integrity. Sandstorms reduce visibility and increase the risk of accidents. Regular checks are essential to maintain safety standards.

Wear And Tear

Constant use leads to wear and tear. Over time, scaffolding components degrade. Rust can weaken metal parts, making them unsafe. Regular inspection identifies damaged parts early. Replacing worn-out elements ensures scaffolding remains secure and reliable.

Improper Assembly

Incorrect scaffolding assembly risks structural failure. Each part must be securely attached. Loose connections can cause instability. Proper training prevents assembly mistakes. Experienced workers ensure each scaffolding setup meets safety guidelines.

Inspection Tools

Inspecting scaffolding in Saudi Arabia ensures safety and compliance in construction. Check for sturdy materials, secure connections, and proper assembly. Regular inspections prevent accidents and maintain construction standards.

Inspecting scaffolding is a crucial step in ensuring construction safety, especially in Saudi Arabia where rigorous standards are in place. You need the right tools to carry out a thorough inspection. These tools not only help in identifying potential hazards but also ensure compliance with safety regulations. From measuring devices to safety gear, each tool plays a unique role in the inspection process. Let’s dive into some essential inspection tools you’ll need on-site.Measuring Devices

Accurate measurements are the backbone of any scaffolding inspection. Ensuring that scaffolding is level and properly aligned can prevent accidents. Tools such as spirit levels and tape measures are indispensable. Have you ever noticed how a slight tilt can make a structure look unstable? That’s why precise measurements are crucial. They help you maintain the integrity of the scaffolding structure.Inspection Tags

Inspection tags are more than just labels; they are your record of safety checks. These tags indicate that scaffolding has been inspected and is safe to use. They often include crucial information like the date of inspection and the inspector’s name. Imagine working on a site with no clear safety records. It would be chaos, right? Inspection tags bring order and accountability to the construction site.Safety Gear

Safety gear is your first line of defense during any inspection. Hard hats, gloves, and safety harnesses are essential. They protect you from potential hazards that may arise during the inspection process. Remember that one time you underestimated the importance of gloves and ended up with a nasty cut? That’s a lesson you don’t want to learn the hard way. Always ensure you’re fully equipped before starting an inspection. Having the right tools is not just about completing a checklist; it’s about creating a safe work environment. Are you equipped with the necessary tools for your next scaffolding inspection? It’s worth considering if you want to ensure both safety and compliance on your construction site.

Credit: www.linkedin.com

Documentation And Reporting

In the bustling construction industry of Saudi Arabia, ensuring scaffolding safety is paramount. Documentation and reporting are essential components in this process. They provide a clear record of inspections, compliance, and follow-up actions. This not only helps in maintaining safety standards but also in meeting legal requirements. But how do you effectively manage these crucial tasks?

Inspection Reports

Inspection reports are the backbone of scaffolding safety. They capture every detail of the inspection, from the condition of the materials to the setup’s stability. Make sure your reports are thorough and accurately reflect the inspection findings. Include photos and notes on any issues discovered. Consider using digital tools to streamline report creation and storage. This ensures easy access and sharing with your team.

Compliance Records

Compliance records are your proof of meeting safety regulations. These documents should detail every step taken to adhere to Saudi Arabia’s construction laws. Keep a checklist of all compliance requirements and tick them off as you meet them. This not only keeps you organized but also reassures stakeholders of your commitment to safety. Regularly updating these records is crucial, especially after inspections.

Follow-up Procedures

Follow-up procedures ensure that any issues found during inspections are addressed promptly. Set clear deadlines for corrective actions and assign responsibilities to team members. Use reminders and alerts to keep everyone on track. Document these procedures meticulously. This creates a transparent trail showing how issues were resolved. Ask yourself: are your follow-up procedures effective enough to prevent future problems?

Engaging with your team about the importance of proper documentation can be a game changer. Share real stories of past incidents that were avoided thanks to diligent reporting. It makes the importance of documentation tangible. Remember, the effort you put into documentation today can save lives tomorrow.

Training And Certification

Discover essential techniques for inspecting scaffolding in construction projects across Saudi Arabia. Ensure safety and compliance by learning key inspection steps. Proper training and certification are crucial for maintaining structural integrity and worker safety on site.

Training and certification are crucial for ensuring the safety and reliability of scaffolding inspections in construction projects across Saudi Arabia. With the potential risks involved in construction work, having well-trained and certified inspectors is non-negotiable. Properly equipped inspectors can help prevent accidents, save lives, and maintain compliance with local regulations. Let’s explore the key areas of training and certification necessary for scaffolding inspection.Inspector Qualifications

To become a scaffolding inspector in Saudi Arabia, specific qualifications are essential. Inspectors should have a solid understanding of construction principles and an aptitude for safety protocols. A background in engineering or construction management can be beneficial. Hands-on experience with scaffolding systems is a must. Inspectors should have a keen eye for detail and the ability to identify potential hazards. This skill set ensures that inspections are thorough and effective. Can you imagine spotting a minor flaw that prevents a major accident? That’s the power of proper qualifications.Ongoing Training

The construction industry is ever-evolving, and so are the standards for scaffolding inspections. Ongoing training is vital to keep inspectors up-to-date with the latest safety practices and technologies. Regular workshops and refresher courses can help maintain high inspection standards. Consider the impact of new materials or construction techniques on scaffolding safety. Continuous learning equips inspectors with the knowledge to adapt to these changes. It also instills confidence in their ability to perform thorough inspections. When was the last time you learned something new that changed how you did your job?Certifying Bodies In Saudi Arabia

In Saudi Arabia, specific organizations offer certification for scaffolding inspectors. These certifying bodies ensure that inspectors meet national standards and guidelines. The Saudi Council of Engineers (SCE) is one prominent organization that provides such certifications. Another key player is the Saudi Standards, Metrology and Quality Organization (SASO), which establishes safety and quality standards. Obtaining certification from recognized bodies assures employers of the inspector’s competence. Would you trust an uncertified inspector with your safety? Certification is the seal of trust in this critical field. Training and certification are not just about meeting legal requirements. They are about building a culture of safety and reliability in construction. As a scaffolding inspector, your qualifications and ongoing learning are your most powerful tools.

Credit: www.instagram.com

Frequently Asked Questions

What Is The Proper Inspection Process For Scaffolding?

Inspect scaffolding by checking structural integrity, securing connections, and ensuring stability. Verify platform safety, guardrails, and access points. Examine for damage or wear. Confirm compliance with safety standards. Regular inspections are crucial for worker safety.

What Is The Salary Of Scaffolding Inspector In Saudi Arabia?

A scaffolding inspector in Saudi Arabia typically earns between SAR 5,000 to SAR 12,000 per month.

How Is Scaffolding Tested?

Scaffolding is tested through visual inspections, load testing, and adherence to safety standards. Qualified professionals ensure stability and safety.

What Is The Inspection Test Plan For Scaffolding?

The inspection test plan for scaffolding includes checking structural integrity, stability, load capacity, and compliance with safety standards. Regular inspections ensure safe usage.

Conclusion

Inspecting scaffolding in Saudi Arabia is crucial for construction safety. Regular checks ensure structural integrity. Identify hazards early to prevent accidents. Use proper tools and techniques. Follow local regulations and standards. Ensure workers are trained for inspections. Maintain detailed records of inspections.

Safety in construction relies on thorough scaffolding checks. Proper inspection leads to safer work environments. Prioritize safety in every project.