Scaffolding helps build safely. It supports workers and materials on site.

In Saudi Arabia, scaffolding is crucial for the construction industry. With its rapidly growing urban landscapes, the demand for sturdy and reliable scaffolding systems is high. These structures ensure safety and efficiency when working on tall buildings and complex architectural designs.

Understanding how scaffolding works is essential for anyone involved in construction. It involves setting up temporary platforms that support workers and materials. These platforms provide stability during construction, allowing tasks to be completed effectively. Knowing the types and components of scaffolding helps workers and engineers choose the right system for each project. This understanding is vital for safety and success in Saudi Arabia’s booming construction sector.

Introduction To Scaffolding

Scaffolding plays a crucial role in construction projects. It provides a temporary structure for workers. In Saudi Arabia, scaffolding ensures safe and efficient building processes. Understanding scaffolding is important for anyone involved in construction.

Importance In Construction

Scaffolding is vital for worker safety. It offers a stable platform to work at heights. Without it, construction tasks become dangerous. Scaffolding supports workers and building materials. It helps in reaching difficult areas safely. This ensures project efficiency and safety.

Overview Of Scaffolding

Scaffolding involves several components. It includes tubes, couplers, and boards. These parts create a framework. Workers assemble scaffolding on-site. This process follows strict guidelines. Scaffolding adapts to different construction needs. It is versatile and can be adjusted. This flexibility is essential in varying project requirements.

Credit: www.facebook.com

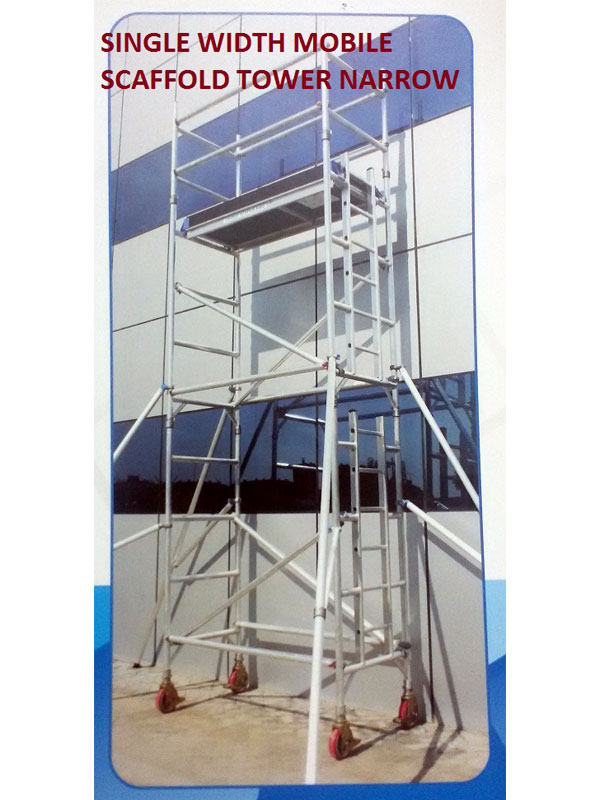

Types Of Scaffolding

Scaffolding plays a crucial role in construction in Saudi Arabia. Different types, like suspended, supported, and rolling scaffolds, provide safe access and support for workers. Each type is chosen based on specific project needs, ensuring efficiency and safety in various construction tasks.

In the construction industry of Saudi Arabia, scaffolding plays a crucial role in ensuring the safety and efficiency of building processes. Different types of scaffolding cater to various construction needs, providing both flexibility and stability. Whether you’re a seasoned contractor or an enthusiast looking to understand more about construction, knowing the types of scaffolding can be vital for your projects. ###Supported Scaffolding

Supported scaffolding is one of the most commonly used types in Saudi Arabian construction. This type of scaffolding is built from the ground up, offering sturdy support for workers and materials. It typically consists of metal poles and wooden planks, creating a secure platform. In Saudi Arabia’s bustling cities, you’ll often see supported scaffolding around high-rise buildings. It’s favored for its ease of assembly and ability to bear heavy loads. If you’re working on a project that requires consistent access to different building heights, supported scaffolding might be your go-to choice. ###Suspended Scaffolding

Suspended scaffolding, on the other hand, is perfect for projects where the ground is not accessible or stable. This type of scaffolding hangs from the top of a building using ropes or chains, providing a flexible working platform. Imagine working on the façade of a skyscraper in Riyadh. Suspended scaffolding allows workers to move up and down easily without the need for a solid foundation below. This can be particularly useful for tasks like painting or window cleaning on tall structures. When considering the right type of scaffolding for your project, think about the specific needs of your construction site. Is the ground suitable for supported scaffolding, or does your project require the adaptability of suspended scaffolding? Understanding these differences can make a significant impact on the success and safety of your construction endeavors in Saudi Arabia.Materials Used

Scaffolding is an essential part of construction in Saudi Arabia. The materials used in scaffolding can significantly impact the safety and efficiency of a construction project. Understanding the different types of materials can help you choose the right one for your needs. Let’s dive into the two most common materials: metal and wood.

Metal Scaffolding

Metal scaffolding is a popular choice in construction due to its strength and durability. It is often made from steel or aluminum. These metals can withstand heavy loads and extreme weather conditions, making them ideal for the harsh climate of Saudi Arabia.

Steel scaffolding is robust and can support large structures. It is fire-resistant and can be reused, making it cost-effective in the long run. However, it is heavier and may require more labor to set up and dismantle.

Aluminum scaffolding, on the other hand, is lightweight and easy to handle. It is resistant to corrosion, which is a significant advantage in coastal areas. Although it may not be as strong as steel, it is suitable for smaller projects and areas with less load requirements.

Have you ever worked with metal scaffolding? It can make a world of difference in a project’s timeline and safety. Choosing the right type of metal can save you time and money. What are your experiences with it?

Wooden Scaffolding

Wooden scaffolding is less common but still used in certain situations. It is typically made from bamboo or timber. This type of scaffolding is often seen in smaller projects or in areas where metal scaffolding is not readily available.

Bamboo scaffolding is lightweight and flexible. It is often used in regions with abundant bamboo resources. Despite its lightweight nature, bamboo is surprisingly strong and can support significant loads. It is also eco-friendly, as bamboo is a renewable resource.

Timber scaffolding, made from wood planks and poles, is another option. It is easy to assemble and disassemble. However, it is less durable than metal scaffolding and can be affected by weather conditions such as rain and humidity.

Have you ever tried wooden scaffolding? It offers a different set of challenges and benefits. For smaller projects or temporary structures, it might be the right choice. What do you think? Would you consider using it?

Choosing the right scaffolding material is crucial for the success of your construction project. Whether you go with metal or wood, make sure it meets your specific needs and local regulations. Your choice can impact not just the efficiency but also the safety of your worksite.

Safety Regulations

Scaffolding in Saudi Arabia ensures worker safety and efficient construction. Strict regulations govern installation, inspection, and use.

Safety is a top priority in the construction industry, especially when scaffolding is involved. In Saudi Arabia, specific regulations ensure that workers and bystanders remain safe while scaffolding is used on construction sites. These rules are not just bureaucratic hurdles; they are life-saving guidelines that every construction company must follow. But what exactly do these regulations entail? ###Government Standards

The Saudi government has set strict standards for scaffolding to ensure safety. The Ministry of Municipal and Rural Affairs (MOMRA) is the primary body overseeing these regulations. They require scaffolding to be made from sturdy materials like steel or aluminum. Saudi standards mandate specific load capacities for scaffolds. This ensures they can support not just the weight of workers, but also the tools and materials they carry. These standards are not just for compliance; they are crucial for preventing accidents. ###Inspection Procedures

Regular inspections are a must. Before scaffolding can be used, a qualified inspector must check it for stability and safety. This isn’t just a one-time thing—scaffolding must be checked at regular intervals during its use. Inspectors look for any signs of wear and tear that could compromise safety. They also ensure that all safety features, like guardrails and base plates, are in place. You might think of inspections as tedious, but they are a vital part of keeping everyone safe. Have you ever wondered if a small oversight could lead to a big problem? In construction, it often can. That’s why inspection procedures are so rigorous. In Saudi Arabia, failing to meet these inspection requirements can result in hefty fines. But the real cost is the risk to human lives. So, it’s not just about following rules—it’s about ensuring that everyone goes home safely at the end of the day. Wouldn’t you agree that these safety regulations are essential for a secure work environment?Installation Process

The installation process of scaffolding is crucial in construction projects. In Saudi Arabia, safety and efficiency are top priorities. Proper installation ensures worker safety and project success. Let’s explore the key steps involved.

Site Preparation

Preparing the site is the first step. Clear the area of debris and obstacles. Ensure the ground is level and stable. Check for underground utilities that could interfere. Safety checks are essential before assembly begins.

Assembly Techniques

Assembly requires precision and skill. Begin with the base structure. Secure it tightly to prevent movement. Use standardized components for consistency. Follow manufacturer guidelines for best results. Regular inspections ensure stability throughout the process.

Credit: www.linkedin.com

Common Challenges

Scaffolding in Saudi Arabia faces challenges like extreme weather and diverse architectural styles. Ensuring safety and stability is crucial. Workers must adapt to regulations and terrain, making training essential.

Scaffolding is an essential part of construction, providing the support and access needed to build safely and efficiently. However, working with scaffolding in Saudi Arabia presents unique challenges. Understanding these challenges can help you plan better and ensure safety on your construction site.Weather Conditions

Saudi Arabia is known for its extreme weather. The scorching heat can be punishing for workers and can also affect the materials used in scaffolding. Metal can become dangerously hot, and wood can warp or crack, compromising stability. Dust storms are another challenge. They can reduce visibility, making it difficult for workers to see what they’re doing. They can also lead to slippery surfaces, increasing the risk of accidents. Have you considered how to protect your team and equipment from these conditions? Simple solutions like scheduling work during cooler parts of the day and using protective covers for scaffolding can make a big difference.Structural Stability

Ensuring structural stability is crucial for scaffolding. In Saudi Arabia, the sandy and uneven terrain can pose difficulties in securing the base of the scaffolding. Imagine setting up scaffolding on a shifting sand base. It’s a recipe for instability. To prevent accidents, you must use base plates and adjustable jacks for a solid foundation. Regular inspections are also essential. Checking for loose bolts or any signs of wear and tear can prevent potential collapses. Are your scaffolding structures checked daily? By addressing these common challenges, you can enhance the safety and efficiency of your construction projects in Saudi Arabia. Each challenge presents an opportunity to improve. Take proactive steps today, and ensure your scaffolding is up to the task.Innovative Technologies

In the dynamic world of construction in Saudi Arabia, innovative technologies are reshaping how scaffolding is designed and used. These advancements not only enhance safety and efficiency but also allow for greater flexibility and cost-effectiveness. Let’s delve into the exciting realm of advanced scaffolding designs and automation in scaffolding that are transforming the industry.

Advanced Scaffolding Designs

Modern scaffolding designs are a game-changer in construction. They offer enhanced safety features, such as non-slip surfaces and guardrails, ensuring worker protection at every height. These designs also allow for easier assembly, cutting down on labor costs and time.

Take, for instance, modular scaffolding systems that can be adjusted to fit the unique contours of any building. This adaptability is crucial, especially in Saudi Arabia’s diverse architectural landscape. By using such systems, you can seamlessly support complex structures, ensuring that construction progresses smoothly.

Additionally, lightweight materials like aluminum are becoming more popular in scaffolding. They offer the dual benefits of strength and ease of handling. Imagine the ease of transporting and assembling scaffolding that’s both strong and light—it’s a win-win for any construction project.

Automation In Scaffolding

Automation is another frontier where scaffolding technology is making strides. Automated scaffolding systems can be programmed to move and adjust themselves, reducing the need for manual labor. This innovation not only speeds up construction but also minimizes risks associated with human error.

Consider the impact of robotic scaffold assembly that precisely fits pieces together with minimal human intervention. This technology is particularly beneficial in high-risk environments where safety is paramount. Wouldn’t you feel more secure knowing that technology is actively working to keep you safe?

Moreover, automated systems can be monitored remotely, allowing for real-time adjustments and maintenance. This means you can oversee and optimize scaffolding operations without being on-site, saving time and resources. Such efficiency is crucial in a fast-paced construction environment where every minute counts.

As you explore these innovative technologies, think about how they can enhance your construction projects. Are there areas where you could integrate advanced designs or automation to improve safety and efficiency? Embracing these innovations not only propels your projects forward but also aligns with the future of construction in Saudi Arabia.

Credit: www.alamy.com

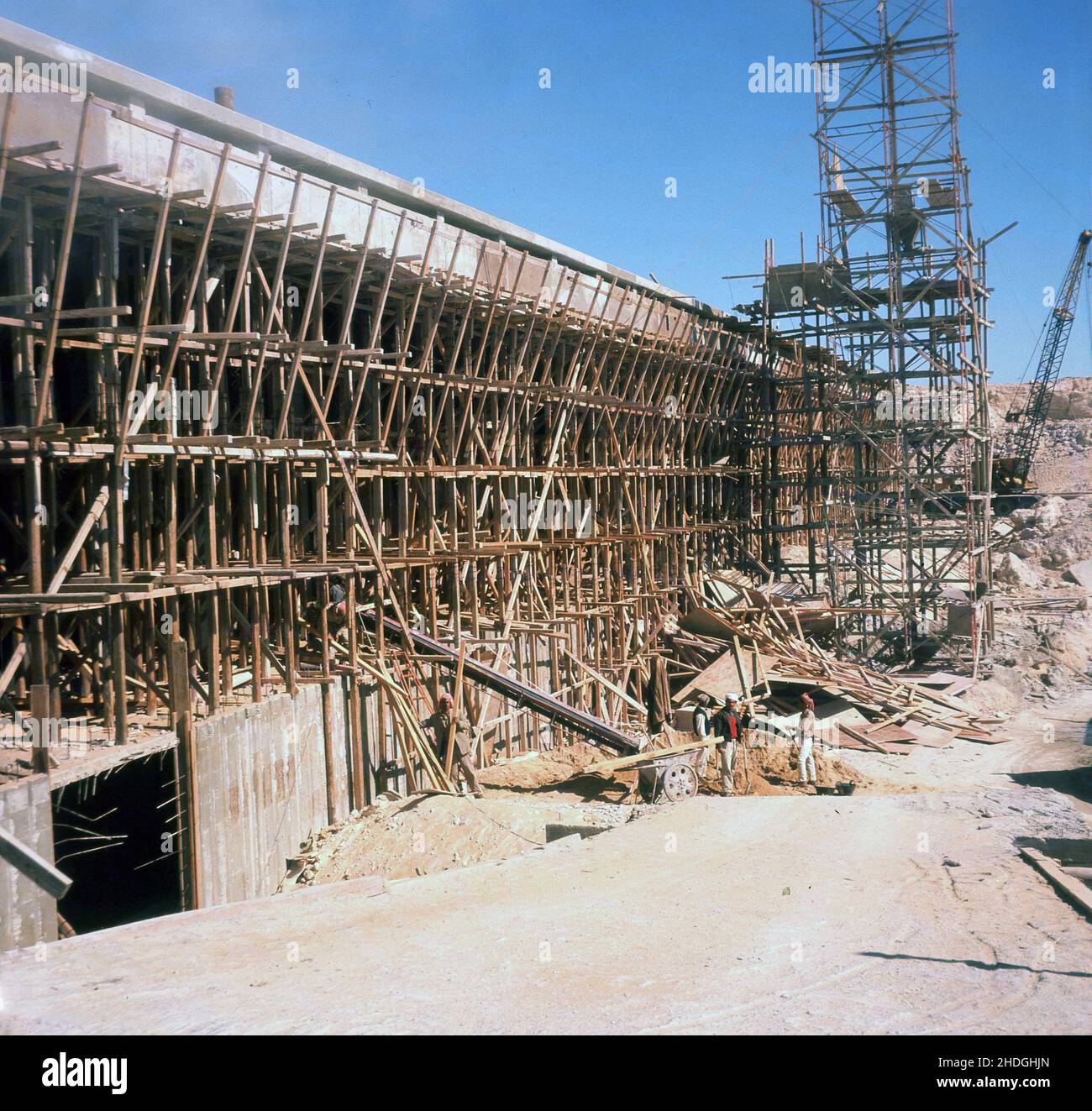

Case Studies

Scaffolding plays a crucial role in construction projects across Saudi Arabia. Understanding its success stories and lessons is vital. This section explores case studies showcasing the effective use of scaffolding.

Successful Projects

One remarkable project is the King Abdulaziz Center for World Culture. Scaffolding supported its unique architectural design. The structure demanded intricate scaffolding arrangements. These arrangements ensured worker safety and project efficiency.

Another successful project is the Riyadh Metro. Scaffolding was essential for station construction. It facilitated quick access to high points. It also allowed seamless coordination among workers.

Lessons Learned

From these projects, timely scaffolding planning is crucial. Early planning prevents delays. It ensures smooth operations.

Another lesson is the importance of quality materials. Durable scaffolding can withstand harsh weather. This is vital in Saudi Arabia’s climate.

Safety measures cannot be overlooked. Regular inspections and maintenance are necessary. They ensure worker safety and structural stability.

Frequently Asked Questions

What Is The Salary Of Scaffolding Engineer In Saudi Arabia?

The salary of a scaffolding engineer in Saudi Arabia typically ranges from $1,500 to $4,000 per month. Experience, qualifications, and location can influence the salary. Specialized skills may lead to higher pay.

What Is The Process Of Scaffolding In Construction?

Scaffolding in construction involves assembling temporary structures. Workers use these to access high areas safely. The process includes planning, erecting, and dismantling. Proper safety measures are crucial.

What Is The Salary Of Scaffolding Supervisor In Saudi Arabia?

A scaffolding supervisor in Saudi Arabia earns between $1,500 and $3,000 per month, depending on experience and qualifications.

What Is The 3 To 1 Rule For Scaffolding?

The 3 to 1 rule for scaffolding means the height must not exceed three times the base width.

Conclusion

Scaffolding plays a crucial role in Saudi Arabia’s construction industry. It ensures worker safety and project efficiency. Understanding its components and uses aids in safer construction practices. With proper scaffolding, projects move faster, minimizing delays. Many construction firms rely on scaffolding for high-quality builds.

It supports various structures, from small buildings to massive skyscrapers. Choosing the right scaffolding type is essential for project success. Always prioritize safety standards and regulations. This knowledge helps in making informed decisions. Successful construction relies on effective scaffolding use.

Stay informed and ensure safe, efficient building practices.