Inspecting scaffolding in Saudi Arabia is crucial for safety. Proper checks prevent accidents and ensure compliance with regulations.

Scaffolding plays a vital role in construction projects, providing necessary support and access. In Saudi Arabia, where construction is booming, scaffolding safety can’t be overlooked. Regular inspections help identify potential hazards and maintain the integrity of the structure. This blog will guide you through the inspection process, ensuring that your scaffolding meets the highest safety standards.

By understanding the key steps and requirements, you can protect workers, avoid costly fines, and contribute to the success of your projects. Let’s dive into how you can effectively inspect scaffolding in Saudi Arabia.

Credit: boshilock.en.made-in-china.com

Importance Of Scaffolding Inspection

The importance of scaffolding inspection in Saudi Arabia cannot be overstated. Regular inspections ensure the safety of workers. They also ensure compliance with local laws. Below, we explore key reasons why inspecting scaffolding is crucial.

Safety Concerns

Scaffolding accidents can lead to serious injuries. Falls from heights are among the most common risks. Broken or unstable scaffolding can collapse. This endangers workers and the public. Regular inspections help identify and fix potential hazards. This keeps everyone safe.

Legal Requirements

Saudi Arabia has strict regulations on scaffolding use. Inspections ensure compliance with these laws. Failure to comply can result in fines and legal actions. Regular checks keep companies within legal boundaries. They also help avoid costly lawsuits.

Types Of Scaffolding

In Saudi Arabia, scaffolding is essential for safe construction work. Different types of scaffolding are used based on the project needs. Each type has unique features and advantages.

Supported Scaffolding

Supported scaffolding is the most common type. It stands on the ground and is built from the base up. This type is stable and secure, making it ideal for many construction tasks.

There are several subtypes of supported scaffolding:

- Frame Scaffolding: Easy to set up and used for simple tasks.

- System Scaffolding: Modular components for complex structures.

- Trestle Scaffolding: Portable and used for smaller jobs.

Supported scaffolding is versatile and safe for workers.

Suspended Scaffolding

Suspended scaffolding hangs from the top of a building. It is used for tasks at great heights. Workers can move the platform up and down as needed.

Common types of suspended scaffolding include:

- Two-point Suspended Scaffolding: Supported by ropes at two points. Commonly used for window washing.

- Multi-point Suspended Scaffolding: Supported at multiple points. Suitable for larger projects.

- Catenary Scaffolding: Uses a horizontal and vertical rope system. Ideal for working on bridges.

Suspended scaffolding offers flexibility for high-rise projects.

Understanding these types helps in choosing the right scaffolding for each job. Ensuring safety and efficiency is crucial in construction.

Inspection Checklist

Inspecting scaffolding is essential for safety in Saudi Arabia. An inspection checklist helps ensure all aspects of the scaffolding are reviewed. This process minimizes the risk of accidents. Here is a detailed inspection checklist to follow.

Structural Integrity

Check the base of the scaffolding. Ensure it’s on a stable surface. Inspect the scaffolding frames. Look for any visible damage or rust. Verify that all connections are secure. Confirm that the scaffolding is level. Make sure the bracing is in place. Check the load capacity. Ensure it matches the requirements.

Safety Measures

Inspect guardrails. Ensure they are in place and secure. Check toe boards. Confirm they are installed correctly. Verify that access ladders are safe. Ensure they are securely attached. Inspect the work platforms. Make sure they are not slippery. Look for any debris or obstructions. Ensure the area is clear. Confirm that workers use safety harnesses. Check that all safety gear is in good condition.

Common Scaffolding Hazards

Scaffolding is essential for construction projects. However, it also poses various hazards. Understanding these common risks is crucial. It ensures worker safety and project efficiency. In this section, we will discuss some of the most common scaffolding hazards. We’ll focus on falls, slips, and structural collapse.

Falls And Slips

Falls and slips are major scaffolding hazards. Workers often work at great heights. Even a small slip can lead to severe injuries or fatalities. Proper guardrails and non-slip surfaces are vital. Workers should also use personal protective equipment. Regular safety training can reduce these risks significantly.

Structural Collapse

Structural collapse is another serious concern. Poorly constructed scaffolds can fail under load. Always ensure that scaffolding is built to standard. Regular inspections are necessary. Look for signs of wear and tear. Check all connections and supports. A small issue can lead to a catastrophic failure.

Required Qualifications For Inspectors

Scaffolding inspections are critical for ensuring safety at construction sites in Saudi Arabia. To perform these inspections effectively, inspectors must have certain qualifications. These qualifications ensure that inspectors have the necessary knowledge and skills to identify potential hazards and ensure compliance with safety regulations.

Certification

Inspectors must hold relevant certifications. In Saudi Arabia, the Saudi Council of Engineers (SCE) offers certification programs. These programs provide essential training in scaffolding safety and inspection. Inspectors should complete these programs to understand the best practices and legal requirements.

Additionally, inspectors may pursue international certifications. Bodies like the Occupational Safety and Health Administration (OSHA) and the International Powered Access Federation (IPAF) offer recognized certifications. These certifications demonstrate a high level of competence and adherence to global safety standards.

Experience

Experience is another crucial qualification for scaffolding inspectors. Inspectors should have hands-on experience in the construction industry. This experience helps them understand the practical challenges and common issues in scaffolding.

Inspectors should ideally have several years of experience. A minimum of three to five years is often recommended. This experience allows inspectors to develop a keen eye for detail and a deep understanding of safety protocols.

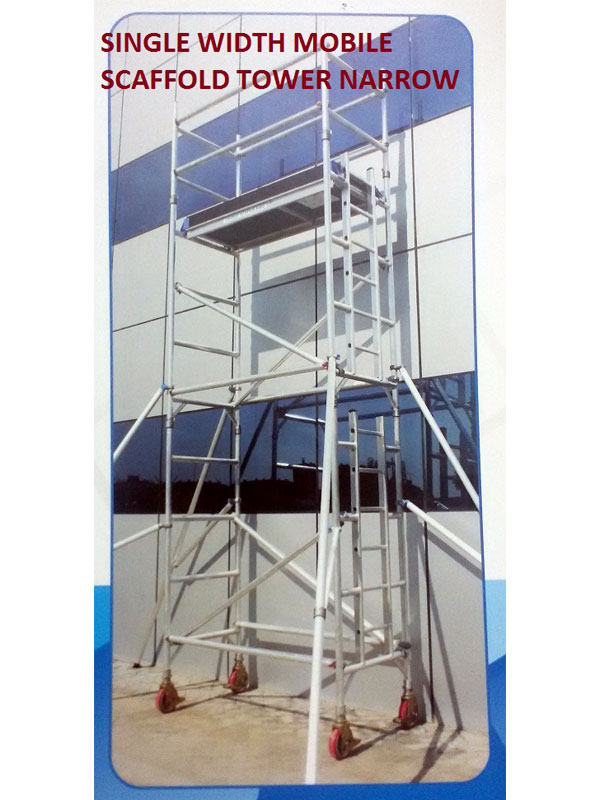

Additionally, having experience in different types of scaffolding is beneficial. This includes suspended scaffolds, supported scaffolds, and mobile scaffolds. Each type has unique inspection requirements and potential hazards.

Here is a summary of the required qualifications for scaffolding inspectors in Saudi Arabia:

| Qualification | Details |

|---|---|

| Certification | Saudi Council of Engineers (SCE) certification, OSHA, IPAF |

| Experience | Minimum 3-5 years in the construction industry |

Credit: www.facebook.com

Inspection Frequency

Ensuring the safety of scaffolding in Saudi Arabia requires regular inspections. These inspections help in identifying potential hazards and maintaining compliance with safety standards. The frequency of these inspections can be categorized into two main types: daily inspections and periodic reviews.

Daily Inspections

Daily inspections are crucial for scaffolding safety. Before use, check for any visible damage. Look for missing components, bent pipes, or loose connections. Ensure the base is stable and secure. Verify that guardrails are in place and platforms are clear of debris. Document any issues found during daily checks. This helps in keeping track of recurring problems. Address any safety concerns immediately to prevent accidents.

Periodic Reviews

Periodic reviews are more detailed than daily checks. Conduct these inspections weekly or monthly, depending on the project size. Examine the entire scaffolding structure thoroughly. Look for any signs of wear and tear that might not be visible during daily inspections. Check the foundation for any shifts or instability. Verify that all safety measures, like harnesses and nets, are in good condition. Review the scaffolding plan to ensure it meets safety regulations. Keep detailed records of these reviews for future reference.

Documentation And Reporting

Ensuring the safety of scaffolding in Saudi Arabia demands rigorous documentation and reporting. Accurate records not only adhere to legal requirements but also enhance overall safety. This section will delve into the essential aspects of documenting and reporting scaffold inspections.

Inspection Reports

Inspection reports are critical for maintaining scaffold safety. These reports provide a detailed record of the scaffold’s condition and any identified issues. They help in tracking the maintenance history and ensuring timely repairs.

Each inspection report should include:

- Date of inspection

- Inspector’s name and credentials

- Scaffold location and description

- Findings and observations

- Photos of identified issues

- Recommended actions

Compliance Records

Compliance records ensure that the scaffolding meets all regulatory standards in Saudi Arabia. These records demonstrate adherence to safety protocols and legal requirements.

Key elements of compliance records include:

- Certification of scaffold components

- Training records of personnel

- Inspection frequency and dates

- Records of repairs and modifications

- Safety meeting minutes

Maintaining up-to-date compliance records is crucial. It provides a clear history of scaffold safety and ensures readiness for audits.

Training For Workers

Training for Workers is crucial to ensure scaffolding safety in Saudi Arabia. Proper training helps workers understand the importance of scaffolding inspection. It also ensures they follow safety protocols and use the scaffold correctly.

Safety Protocols

Safety protocols are the backbone of scaffolding training. Workers must know how to handle tools and equipment safely. They should understand the risks and how to avoid them.

Key safety protocols include:

- Wearing personal protective equipment (PPE)

- Inspecting scaffolding before use

- Following safe work practices

Proper Usage

Proper usage training is essential. Workers must know how to use the scaffolding correctly. This reduces the risk of accidents and ensures the job is done efficiently.

Training should cover:

- Setting up the scaffold correctly

- Using tools and materials safely

- Understanding load limits

By following these steps, workers can ensure their safety and the safety of others.

Credit: boshilock.en.made-in-china.com

Frequently Asked Questions

What Is Scaffolding Inspection?

Scaffolding inspection is the process of examining scaffolding for safety and compliance. It includes checking structural integrity, stability, and proper assembly. Regular inspections help prevent accidents.

How Often Should Scaffolding Be Inspected?

Scaffolding should be inspected before each use, after any alterations, and at least every 7 days. Frequent inspections ensure safety and compliance with regulations.

Who Can Inspect Scaffolding In Saudi Arabia?

In Saudi Arabia, a competent person with relevant training and experience can inspect scaffolding. They should understand safety standards and legal requirements.

What Are Common Scaffolding Inspection Checkpoints?

Common checkpoints include checking for damaged components, proper assembly, secure fittings, and adequate support. Inspecting guardrails, platforms, and access points is essential.

Conclusion

Regular scaffolding inspections are crucial in Saudi Arabia. They ensure safety and efficiency. Follow the steps mentioned to avoid accidents and delays. Train your team well. Regularly update them on safety protocols. Inspect materials thoroughly. Check connections and stability. Report any issues immediately.

Proper inspection practices save lives and costs. Prioritize safety at every stage. Your construction project will benefit greatly. Stay compliant with local regulations. This ensures smooth operations and a safer working environment. Always prioritize safety in all your scaffolding activities.