Scaffolding is essential for construction projects in Saudi Arabia. It ensures worker safety and efficiency.

Building scaffolding may seem complex, but with the right guidance, it’s manageable. Saudi Arabia’s construction standards demand precise methods and materials. This blog will explain the steps to create sturdy scaffolding, ensuring compliance with local regulations. You will learn about the necessary tools, materials, and safety measures.

By the end, you’ll be equipped to set up scaffolding safely and effectively. Whether you are a contractor or a DIY enthusiast, this guide will help you understand the process. Let’s get started on making scaffolding for your next project in Saudi Arabia.

Introduction To Scaffolding In Saudi Arabia

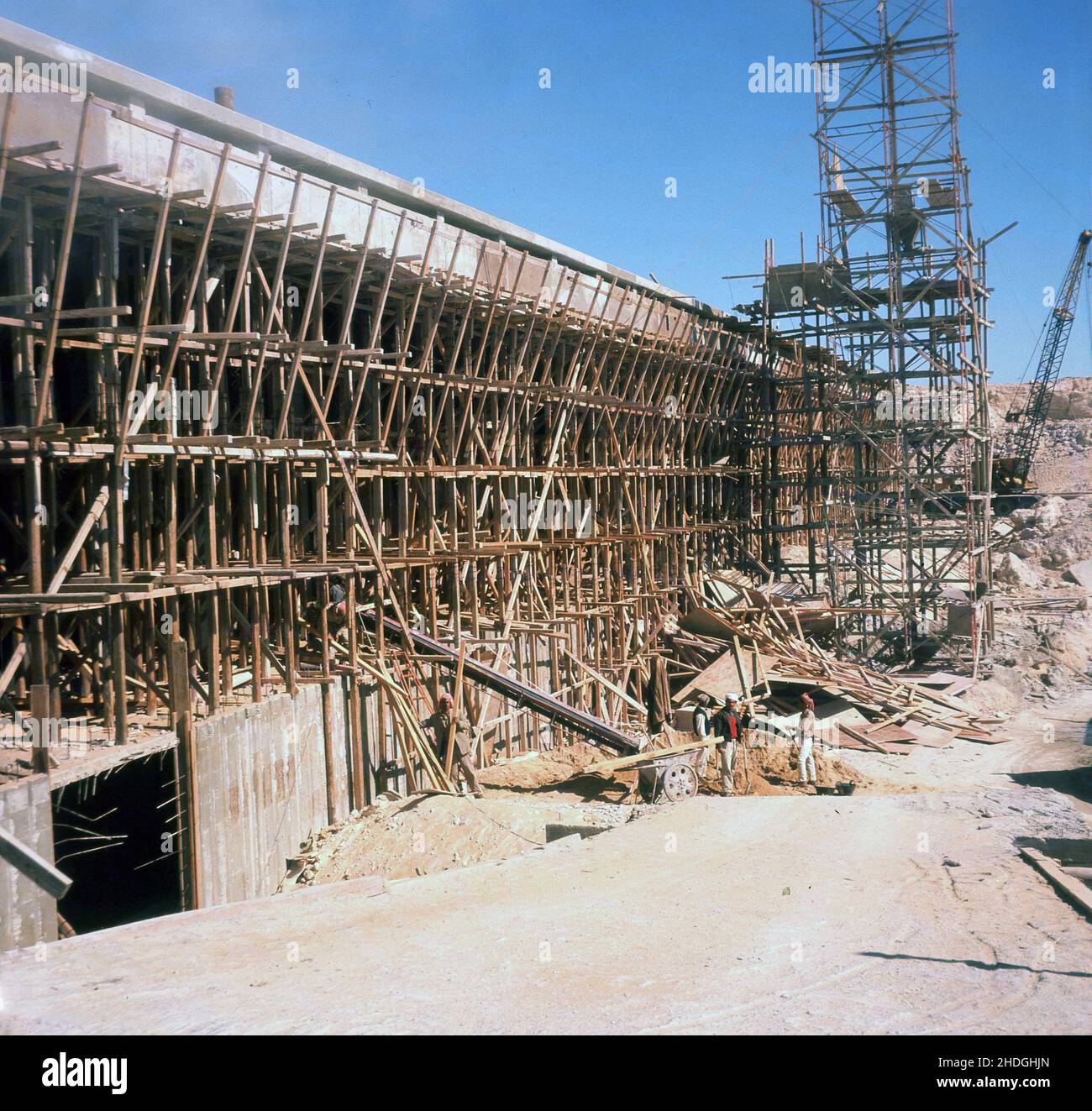

Scaffolding plays a crucial role in the construction sector worldwide. In Saudi Arabia, its importance is paramount. The Kingdom is witnessing rapid urbanization and infrastructure development. These projects demand robust and safe scaffolding systems. Understanding scaffolding is vital for construction success in Saudi Arabia.

Importance Of Scaffolding

Scaffolding ensures worker safety on construction sites. It provides a stable platform for workers and tools. Proper scaffolding minimizes the risk of falls and accidents. This is essential in high-rise projects and complex structures. Quality scaffolding boosts productivity and efficiency. It allows workers to perform tasks at various heights safely. In Saudi Arabia, scaffolding adherence to safety standards is critical. It ensures compliance with local regulations and international guidelines.

Overview Of Construction Industry

Saudi Arabia’s construction industry is booming. Mega projects like NEOM and Vision 2030 drive growth. These projects require advanced construction techniques and materials. Scaffolding systems support these initiatives with safety and precision. The demand for skilled labor and quality equipment is rising. Construction companies invest in training and modern scaffolding solutions. This ensures projects meet deadlines and safety requirements. The construction industry in Saudi Arabia is a key economic driver. Scaffolding remains an integral part of its success.

Types Of Scaffolding

Scaffolding in Saudi Arabia involves various types like single, double, and suspended scaffolding. Each type serves specific construction needs, ensuring safety and efficiency. Proper assembly and understanding of these structures are crucial for successful building projects.

Scaffolding is a crucial part of construction, especially in Saudi Arabia’s booming building industry. It’s like the backbone of any project, offering workers a stable platform to carry out their tasks safely and efficiently. But did you know there are different types of scaffolding, each suited to specific tasks and conditions? Understanding these types can make a significant difference in the success of your project. ###Supported Scaffolding

Supported scaffolding is probably the most common type you’ll encounter. It’s built from the ground up, providing a sturdy and reliable platform. Imagine building a Lego tower; it starts from the bottom and gains strength as it rises. This type of scaffolding is ideal for projects that require heavy loads or multiple workers at different levels. When I worked on a project in Riyadh, we used supported scaffolding extensively. It allowed us to manage tasks seamlessly, even in the busy heart of the city. Have you considered how supported scaffolding could streamline your next project? ###Suspended Scaffolding

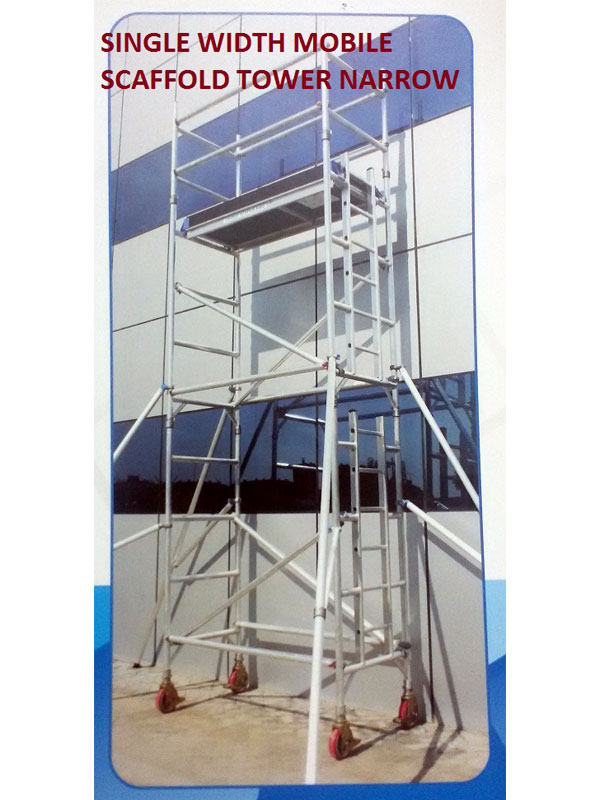

Suspended scaffolding hangs from the roof or upper part of a structure. Think of it like a swing, but much more stable and secure. It’s perfect for tasks that need access to higher floors without ground support. If you’re working on a high-rise in Jeddah, suspended scaffolding could be your best friend. It saves time and space, especially in tight urban areas. Are there parts of your building that seem unreachable? Suspended scaffolding might just be the answer. ###Rolling Scaffolding

Rolling scaffolding is all about mobility. It’s like a wheeled cart, making it easy to move around. This is particularly useful for tasks that require frequent repositioning, like painting or electrical work. When I assisted with a project in Dammam, rolling scaffolding helped us move swiftly along the building facade. You can save valuable time by not having to dismantle and rebuild the structure repeatedly. Could rolling scaffolding be the solution to your project’s efficiency hurdles? Understanding the types of scaffolding and choosing the right one can boost safety and productivity on your site. Are you ready to elevate your construction game in Saudi Arabia?Materials Used In Scaffolding

When working on construction projects in Saudi Arabia, using the right materials for scaffolding can make a world of difference in terms of safety and efficiency. The scaffolding structure is a critical component that provides support and access to various parts of a building during construction or maintenance.

Common Materials

Various materials are commonly used in scaffolding, each with its own set of advantages. Steel is one of the most popular choices due to its strength and durability. It can bear heavy loads and withstand harsh weather conditions, which is crucial in Saudi Arabia’s climate.

Aluminum is another common material, known for being lightweight yet strong. It is easier to transport and assemble compared to steel. This can save valuable time on construction sites, allowing workers to be more productive.

Wooden scaffolding is less common but still used in certain scenarios. It’s cost-effective and easier to procure, but it may not offer the same level of durability and strength as metal scaffolding. This makes it more suitable for smaller projects or temporary structures.

Choosing The Right Material

Choosing the right material for your scaffolding largely depends on the specific requirements of your project. Consider the height of the building, the weight the scaffold needs to support, and the duration of the project.

If you are working on a high-rise building, steel scaffolding might be your best bet due to its strength and stability. On the other hand, for smaller projects or quick tasks, aluminum scaffolding can provide the flexibility and ease of use you need.

Think about the environment where the scaffolding will be used. Saudi Arabia’s climate can be extreme, so materials that can withstand high temperatures and occasional sandstorms are preferable. Steel and aluminum both hold up well under such conditions, but it’s crucial to ensure they are well-maintained to avoid any safety issues.

Have you ever worked on a project where the scaffolding material made a significant difference in your workflow? Choosing the right material can not only enhance safety but also improve efficiency, saving you time and money in the long run.

Credit: thearabweekly.com

Designing Scaffolding Structures

Designing scaffolding structures in construction requires careful planning. It ensures safety and efficiency. In Saudi Arabia, the demand for robust scaffolding is high. The construction industry is booming. Understanding the design principles is crucial for successful projects. Let’s explore the basics of scaffolding design.

Basic Design Principles

Scaffolding design starts with understanding its purpose. It supports workers and materials. The structure must be stable and strong. Use quality materials for durability. Ensure the scaffold can withstand environmental factors. Wind and sandstorms are common in Saudi Arabia. Safety is the top priority.

Consider the type of scaffolding needed. There are different types for different tasks. Choose the right one for the job. Modular scaffolds offer flexibility. They can be easily adjusted. Tube and coupler scaffolds provide strength. They are ideal for heavy loads.

Load Calculations

Load calculations are essential in scaffolding design. They determine the weight the scaffold can bear. Consider both static and dynamic loads. Static loads include the weight of materials. Dynamic loads involve the movement of workers.

Calculate the load capacity accurately. Overloading can cause accidents. Use standard formulas for load calculations. Factor in safety margins. This ensures the scaffold remains safe under pressure.

Regular inspections are necessary. Check the scaffold for signs of wear. Replace damaged parts immediately. This maintains the scaffold’s integrity. Safety must always come first in scaffolding design.

Safety Standards And Regulations

Ensuring scaffolding safety in construction in Saudi Arabia involves following specific standards and regulations. Proper training, regular inspections, and using quality materials are essential. Compliance with these rules helps prevent accidents and ensures worker safety on construction sites.

Ensuring safety in construction is crucial, especially when it involves scaffolding. In Saudi Arabia, strict safety standards and regulations are put in place to protect workers and ensure structural integrity. As a builder or contractor, understanding and adhering to these regulations is not just a legal requirement but a moral obligation. ###Saudi Arabian Regulations

Saudi Arabia has specific regulations governing scaffolding, designed to maintain high safety standards. The Ministry of Municipal and Rural Affairs outlines clear guidelines for scaffold construction, emphasizing the need for stability and strength. You must ensure that scaffolding is built using approved materials and techniques. Regular inspections are mandatory. Have you ever paused to think about the consequences of overlooking these checks? It’s not just about compliance; it’s about safeguarding lives. ###International Standards

International standards also play a vital role in shaping scaffolding practices in Saudi Arabia. The International Labour Organization (ILO) and Occupational Safety and Health Administration (OSHA) provide frameworks that influence local guidelines. Aligning with these standards means adopting best practices recognized globally. Picture this: a construction site where international protocols are upheld, reducing the risk of accidents significantly. Wouldn’t you want your site to be a benchmark for safety? International standards emphasize detailed risk assessment and proper worker training. Implementing these can transform your site into a safer place. Think about how a well-trained team and a risk-free environment can boost your project’s success. Safety in scaffolding construction isn’t just about following rules. It’s about creating a culture of care and responsibility. As you plan your projects, consider how these regulations and standards can be integrated seamlessly. Are you ready to make your construction site a model of safety excellence?

Credit: www.ulmaconstruction.com

Assembling Scaffolding

Constructing scaffolding in Saudi Arabia requires precise planning and adherence to safety standards. Skilled workers assemble the framework using durable materials. Properly secured scaffolding ensures safe access for construction tasks at heights.

Assembling scaffolding is a critical step in any construction project, ensuring safety and efficiency on the worksite. In Saudi Arabia, where the construction industry is booming, mastering the art of scaffolding assembly can set you apart as a skilled worker. It’s not just about putting pieces together; it’s about ensuring stability and safety. Whether you’re working on a small renovation or a massive skyscraper, knowing how to assemble scaffolding can make all the difference. Let’s dive into the key steps and tools you’ll need to get the job done right. ###Step-by-step Assembly

Begin by laying out all the scaffolding components on a flat surface. Ensure you have enough space to organize each piece, making it easier to identify what you need next. Start with the base plates. These are crucial for stability and must be placed on a solid surface. Use a spirit level to check the evenness of the ground, adjusting as necessary. Next, attach the vertical standards to the base plates. Secure them firmly to ensure they don’t wobble. Double-check all connections to guarantee safety. Add the horizontal ledgers. These create the framework and must be aligned correctly to support the structure. You can use a tape measure to ensure precision. Finally, install the diagonal braces. They provide additional stability, especially in windy conditions. Make sure they form an ‘X’ shape for maximum strength. ###Tools And Equipment

Having the right tools is essential for assembling scaffolding efficiently. A basic toolkit should include a hammer, wrench, and spirit level. These tools help ensure that every component is secure and aligned properly. Safety gear is a must. Equip yourself with a hard hat, safety harness, and gloves. Working at height requires extra precautions to prevent accidents. Consider investing in a scaffolding trolley. It makes moving heavy components easier and speeds up the assembly process. It’s a small investment that can save you time and effort. Reflect on the last time you assembled something complex. How much easier would it have been with the right tools and a clear plan? Applying this mindset to scaffolding assembly can greatly enhance your efficiency and safety on the job.Maintenance And Inspection

Scaffolding in construction requires regular maintenance and inspection to ensure safety. Check for damaged parts and secure connections. Follow local regulations and standards for safe assembly and use.

Maintaining and inspecting scaffolding in construction is crucial for safety and efficiency, especially in Saudi Arabia’s dynamic building industry. Proper maintenance ensures the scaffolding remains robust and reliable, while regular inspections prevent potential hazards. Let’s dive into some actionable tips and protocols to keep your scaffolding in top shape.Regular Maintenance Tips

Regular maintenance is the backbone of scaffolding safety. Always clean scaffolding components after use to remove dust and debris. This simple act can extend the lifespan of your equipment. Consider setting a maintenance schedule. Document each session to track wear and tear. Regularly apply protective coatings to metal parts to prevent rust in Saudi Arabia’s humid coastal regions. Check for damaged parts frequently. Loose bolts or bent frames can compromise the entire structure. Make it a habit to replace faulty parts immediately.Inspection Protocols

Inspection is more than a routine task; it’s a safety measure. Begin each workday with a visual check of all scaffolding components. Identify any irregularities or damage. Employ a checklist tailored to your site’s needs. Include checks for stability, alignment, and secure connections. This ensures no detail is overlooked. Engage a qualified inspector for a thorough review at regular intervals. Their expertise might reveal issues unnoticed in daily checks. Wouldn’t you prefer peace of mind knowing your scaffolding is safe for your team? Involve your team in the inspection process. Encourage them to report any concerns immediately. Their firsthand experience with the scaffolding can be invaluable. By implementing these maintenance and inspection strategies, you ensure the safety and efficiency of your construction project. What steps will you take today to enhance your scaffolding practices?Common Challenges And Solutions

Scaffolding is crucial in construction projects across Saudi Arabia. It ensures safety and efficiency during building processes. Yet, creating scaffolding systems presents challenges. Addressing these challenges is key for successful projects. Understanding common issues helps in finding effective solutions.

Weather Conditions

Saudi Arabia faces extreme weather conditions. High temperatures and sandstorms are common. These elements impact scaffolding stability. Strong winds can cause scaffolding to sway. Sand accumulation weakens joints and connections. Heat exposure affects metal parts. Metal expands, causing alignment issues.

Solutions involve using weather-resistant materials. Heat-treated steel maintains integrity in high temperatures. Regular inspections ensure stability. Cleaning routines prevent sand build-up. Protective covers shield scaffolding during storms. Engineers design structures to withstand wind forces.

Site-specific Issues

Every construction site has unique challenges. Terrain can be uneven or rocky. This affects scaffolding installation. Limited space makes scaffolding setup difficult. Urban sites face congestion. High-rise projects require complex scaffolding systems.

Adaptation is crucial for overcoming site-specific issues. Custom scaffolding designs suit varied terrains. Adjustable base plates help stabilize on uneven ground. Compact scaffolding fits tight spaces. Engineers plan scaffolding layouts to avoid congestion. Modular systems allow flexibility in high-rise projects.

Training And Certification

Learn essential skills for scaffolding construction in Saudi Arabia. Gain certification to ensure safety and compliance. Training covers techniques, tools, and local regulations.

In the world of construction, particularly in Saudi Arabia, safety and efficiency are paramount. Proper training and certification for scaffolding can mean the difference between a successful project and a dangerous work environment. Whether you’re a seasoned professional or new to the field, understanding the ins and outs of training and certification is crucial. This section will guide you through the essentials, ensuring you’re not just compliant, but also confident in your skills.Training Programs

The foundation of any competent scaffolding professional is a comprehensive training program. In Saudi Arabia, these programs are designed to cover everything from basic safety measures to advanced construction techniques. You’ll often find modules that teach proper erection and dismantling procedures, critical for preventing accidents. Many training centers offer hands-on experience. This gives you the opportunity to practice in real-world scenarios. Imagine the confidence boost when you know exactly how to safely handle every component of the scaffolding structure. Interactive sessions and workshops are also part of the curriculum. They allow for peer learning and immediate feedback from instructors. Have you ever thought about how much you can learn just by watching someone else’s technique or receiving constructive criticism?Certification Requirements

Once training is complete, certification is your next step. In Saudi Arabia, obtaining a scaffolding certification isn’t just a formality—it’s a legal requirement. This ensures that every worker on the site meets national safety standards. Certification exams typically assess your knowledge of safety regulations and construction best practices. You’ll need to demonstrate proficiency in both theoretical and practical aspects. Do you feel ready to prove your skills under pressure? Renewal of certification is also crucial. It ensures you stay updated with the latest safety standards and technological advancements. This continuous learning process is vital, especially in a field that evolves as rapidly as construction. In your journey to becoming a certified scaffolder, consider the value of thorough preparation and continuous education. How will you ensure your skills remain sharp and relevant in this ever-changing industry?

Credit: www.alamy.com

Future Trends In Scaffolding

The construction industry in Saudi Arabia is evolving. Scaffolding, a crucial part of construction, is also changing. Future trends in scaffolding are shaping how projects are built. These trends focus on safety, efficiency, and sustainability.

Technological Advancements

Technology is changing scaffolding. Smart scaffolding systems are becoming popular. These systems use sensors to monitor safety. They can detect structural weaknesses early. This helps prevent accidents.

Robotics is another trend. Robots can assemble and disassemble scaffolding. This reduces the need for manual labor. It also increases precision and speed. Drones are used for inspections. They can reach high places easily. This ensures thorough checks without putting workers at risk.

Sustainable Practices

Sustainability is important in modern construction. Eco-friendly scaffolding materials are being developed. Bamboo and recycled aluminum are examples. These materials reduce environmental impact.

Reusable scaffolding parts are also in demand. They minimize waste. Modular scaffolding systems support sustainability. They allow for easy assembly and disassembly. This reduces the need for new parts. Efficient use of resources is essential for a greener future.

Frequently Asked Questions

How To Build Scaffolding Step By Step?

Start by inspecting the site and planning the scaffolding layout. Assemble the base plates and frames. Secure braces, platforms, and guardrails. Ensure everything is level and stable. Conduct a final safety check before use.

What Is The Salary Of Scaffolding Engineer In Saudi Arabia?

A scaffolding engineer in Saudi Arabia typically earns between $2,500 and $5,000 per month, depending on experience.

What Is The Process Of Scaffolding In Construction?

Scaffolding in construction involves erecting temporary structures to support workers and materials. It ensures safety and accessibility at heights. The process includes planning, assembling, using, and dismantling the scaffold. Proper training and adherence to safety standards are crucial.

What Is The 3 To 1 Rule For Scaffolding?

The 3 to 1 rule for scaffolding means the height should not exceed three times the base width for stability.

Conclusion

Creating scaffolding in Saudi Arabia requires attention to safety and regulations. Always use quality materials and follow local standards. Regular inspections ensure stability. Training workers on proper setup is crucial. Efficient planning saves time and reduces risks. Adhering to these practices guarantees a safer construction environment.

Understanding these steps simplifies the process. Reliable scaffolding supports successful projects. Keep safety a priority.