What is the maximum height of mobile scaffold in construction in Saudi Arabia? The answer is 12 meters.

Saudi Arabian regulations are strict about scaffolding height for safety reasons. Construction safety is crucial worldwide. In Saudi Arabia, the rules are clear and strict. Mobile scaffolds are essential in construction for workers to reach high places. These scaffolds must be stable and secure.

The maximum allowed height ensures safety for all workers. Understanding this regulation helps prevent accidents and injuries. It is vital for construction companies to comply with these rules. Doing so ensures a safe working environment. This blog will explore the reasons behind this regulation and its importance. We will look into the specifics of mobile scaffold use in Saudi Arabia. Safety is always a priority in construction. Let’s dive into why this height limit is set and its benefits.

Introduction To Mobile Scaffold

Mobile scaffolds are crucial for construction safety and efficiency in Saudi Arabia. Regulations cap the maximum height at 12 meters. This ensures stability and worker safety, aligning with industry standards.

### Introduction to Mobile Scaffold In the bustling world of construction, ensuring the safety and efficiency of workers is crucial. Mobile scaffolds have become indispensable in this regard, especially in countries like Saudi Arabia where construction is thriving. Understanding the nuances of mobile scaffolding can enhance your project’s safety and productivity. ###Definition

Mobile scaffolds are temporary structures that provide a stable platform for workers to perform tasks at various heights. Unlike static scaffolds, they come with wheels, allowing easy movement across the site. Their design includes platforms, frames, and braces, all engineered to support significant weight. These scaffolds can be assembled and disassembled quickly, saving time and labor costs. ###Importance In Construction

Mobile scaffolds are vital for tasks requiring frequent relocation, such as painting or electrical work. Their flexibility means you can adjust their height to suit different job needs, enhancing efficiency. Safety is a top priority in construction, and mobile scaffolds minimize fall risks by providing secure platforms. They also reduce the physical strain on workers, as there’s no need to repeatedly climb up and down ladders. In Saudi Arabia, where construction projects often reach impressive heights, mobile scaffolds ensure workers can operate safely and effectively. But what is the maximum height for these scaffolds? Knowing this can help you plan better and adhere to regulations. Have you ever been on a site where mobility made all the difference? Embracing mobile scaffolds might just be the game-changer you need.Regulations In Saudi Arabia

When working with mobile scaffolding in Saudi Arabia, understanding the local regulations is crucial for safety and compliance. The rules here are not just about maintaining order; they are vital to ensuring the well-being of everyone involved in construction. Knowing these regulations can prevent accidents and help you avoid hefty fines.

Governing Bodies

The primary authority overseeing construction regulations in Saudi Arabia is the Ministry of Municipal and Rural Affairs (MOMRA). They set the standards for construction practices, including scaffolding. MOMRA works closely with other agencies to ensure safety and compliance across all projects.

The Saudi Building Code (SBC) also plays a significant role. It provides detailed guidelines on construction safety, which includes mobile scaffolding. Familiarize yourself with the SBC to ensure your scaffolding practices meet all necessary standards.

Safety Standards

Safety is paramount in Saudi construction sites. Mobile scaffolds must adhere to strict height limits to prevent accidents. Typically, the maximum height allowed is determined by the scaffold’s design and the manufacturer’s instructions.

It’s essential to conduct regular inspections. This ensures that your scaffolding is stable and secure, preventing potential hazards. Frequent checks can make a big difference in maintaining safety standards.

Proper training for workers using scaffolding is also a requirement. Are your workers equipped with the knowledge they need to operate safely? Ensuring they are trained can protect both them and your project from unforeseen issues.

Keep these regulations in mind when planning your construction projects. Doing so not only ensures compliance but also fosters a safe working environment for everyone involved. Are you ready to take the necessary steps to meet these standards?

Maximum Height Requirements

Understanding the maximum height requirements of mobile scaffolds in Saudi Arabia is crucial for ensuring safety and compliance in construction projects. These regulations aim to prevent accidents and maintain structural integrity. Let’s delve into the specific legal limits and factors influencing the height of mobile scaffolds.

Legal Limits

In Saudi Arabia, the maximum height of mobile scaffolds is regulated by the Ministry of Municipal and Rural Affairs. The legal limit for mobile scaffold height is 12 meters. This restriction ensures the stability of the scaffold under various conditions. Strict adherence to this limit is mandatory for all construction sites.

Factors Influencing Height

Several factors influence the maximum height of mobile scaffolds. The primary factor is the scaffold’s load capacity. The weight of workers, tools, and materials can affect stability. Wind speed and weather conditions also play a significant role. High winds can make tall scaffolds unsafe. The type of ground surface is another factor. Uneven or soft ground can compromise the scaffold’s stability.

Scaffold design and construction are crucial. Proper assembly and securing of the scaffold are essential for maintaining its height limits. Regular inspections and maintenance ensure continued safety. Following these guidelines helps in maintaining safe and effective scaffolding practices.

Credit: www.amazon.sa

Construction Site Safety

Ensuring safety on a construction site is like being the captain of a ship—you must be vigilant and proactive. The bustling environment of a construction site in Saudi Arabia, especially when dealing with mobile scaffolds, demands a keen eye for detail and adherence to safety protocols. One small oversight can lead to significant consequences, making safety a non-negotiable priority.

Inspection Procedures

Before you even think about climbing that scaffold, inspection is key. Regular checks help in identifying any potential hazards. These inspections should be done daily, and any issues, no matter how minor, must be addressed immediately.

Use a checklist to ensure nothing is missed. Are the wheels locked? Is the base stable? Such questions can save lives. Remember, a thorough inspection can often be the difference between a safe workday and a trip to the hospital.

Safety Equipment

Would you ride a bike without a helmet? The same principle applies on a construction site. Wearing the right safety gear is crucial. Hard hats, gloves, and safety boots are your best friends.

Harnesses should always be used when working at significant heights. They’re not just a recommendation—they’re a lifesaver. Ensure your team is equipped with all necessary gear before starting work.

Safety is a collective effort. Encourage your team to voice any safety concerns. It could be as simple as a missing guardrail or a loose plank. When everyone is alert, the risk of accidents decreases significantly.

Have you ever witnessed a near-miss on site? It’s a heart-stopping moment that drives home the importance of safety. Share these stories with your team to reinforce the importance of vigilance.

In the fast-paced world of construction, taking a moment to prioritize safety can seem like a delay. But remember, it’s always better to be safe than sorry. What safety measures do you have in place on your site?

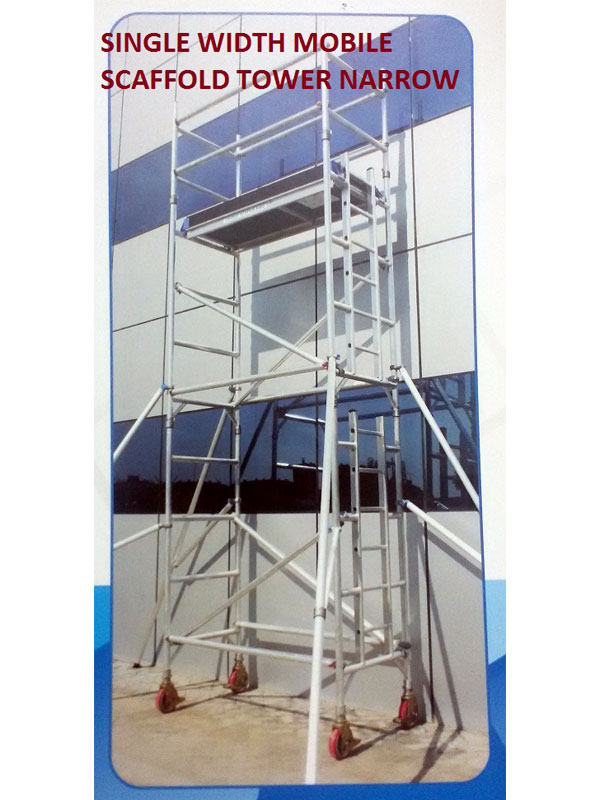

Types Of Mobile Scaffold

Understanding the types of mobile scaffolds can be crucial for anyone in the construction industry, especially when working at heights. Mobile scaffolds offer versatility and mobility, allowing workers to maneuver easily around construction sites. But have you ever wondered what types of mobile scaffolds are available and how they can impact your project in Saudi Arabia? Let’s dive into the specifics and see how these different types can make your work safer and more efficient.

Supported Scaffolds

Supported scaffolds are one of the most common types you’ll encounter. They are built from the ground up and are supported by poles, frames, and other rigid supports. Imagine building a stable platform that can be moved around your site. You have the freedom to adjust the height and shape depending on your needs. This type is perfect for tasks that require stability and durability.

Have you ever been on a construction site where you needed to reach varying heights quickly? Supported scaffolds can be your go-to solution. They can be assembled and dismantled swiftly, saving precious time and energy. Consider how much easier it would be to have a scaffold that adapts to your every need, offering both security and flexibility.

Suspended Scaffolds

Suspended scaffolds are a different beast altogether. They hang from the top of a structure using ropes or cables, providing access to high areas without the need for ground support. Picture a window cleaner on a skyscraper; that’s the power of suspended scaffolds. They allow you to work at height without cumbersome ground setups.

These scaffolds are incredibly useful for tasks like painting or maintenance on tall buildings. Ever tried reaching a high spot without having to set up a massive framework below? Suspended scaffolds give you that freedom, letting you float seamlessly above ground while maintaining safety. They are ideal for projects where the ground space is limited.

Both types of scaffolds have their unique benefits, but which one suits your project best? Consider the nature of your work, the environment, and the required height. What challenges do you face, and how can these scaffolds help overcome them? Take a moment to reflect on your needs and make an informed choice.

Credit: www.facebook.com

Installation Guidelines

Mobile scaffolds in Saudi Arabia can typically reach a maximum height of 12 meters. Safety regulations are strict, ensuring secure construction operations at elevated levels. Proper installation and adherence to guidelines are crucial to maintain worker safety.

When working with mobile scaffolds in construction, especially in Saudi Arabia, following proper installation guidelines is crucial for safety and efficiency. These guidelines ensure that scaffolds are set up correctly and can support the maximum height allowed, adhering to local regulations. Understanding the installation process will not only help you avoid common mistakes but also ensure a secure working environment. Let’s dive into the step-by-step process and highlight some common pitfalls.Step-by-step Process

1. Site Evaluation: Start by assessing the worksite. Check for uneven surfaces, obstacles, and overhead hazards. This initial step prevents issues during scaffold setup. 2. Scaffold Selection: Choose a scaffold type suitable for your project needs. Consider the height, weight capacity, and mobility. Make sure it’s fit for the specific task at hand. 3. Component Check: Inspect all scaffold components. Look for any damage or wear and tear. Ensuring every piece is in good condition is key to a stable structure. 4. Assembly: Begin assembling the scaffold following manufacturer instructions. Connect frames and braces securely. Double-check each connection for tightness. 5. Stability Measures: Implement stability measures like outriggers or braces. These elements are essential for maintaining balance, especially at greater heights. 6. Safety Features: Add safety features such as guardrails and toe boards. These prevent falls and enhance worker safety. Missing these can lead to serious accidents. 7. Final Inspection: Conduct a thorough inspection once assembled. Verify the scaffold is level and secure. A final check ensures readiness for safe use.Common Mistakes

– Ignoring Site Conditions: Many overlook site conditions, leading to unstable scaffolds. Always evaluate the terrain before setup. – Skipping Component Checks: Failing to inspect parts can result in collapses. Regular checks are crucial for scaffold integrity. – Improper Assembly: Misaligning components or skipping steps in assembly can compromise the scaffold’s structure. Follow instructions meticulously. – Neglecting Safety Features: Forgetting guardrails or toe boards increases fall risk. Prioritize adding these elements. – Overloading: Exceeding weight limits due to misjudgment can lead to scaffold failure. Always adhere to specified capacities. Have you ever been in a situation where neglecting these guidelines caused a hiccup in your project? How did you tackle it? Share your insights below; your experience could be invaluable to others.Maintenance And Inspection

Maintenance and inspection are crucial for mobile scaffolds in Saudi Arabia. Regular checks and timely repairs ensure safety and durability. Proper maintenance extends the lifespan of scaffolds. It also prevents accidents and legal issues. Below, we’ll discuss essential aspects of maintenance and inspection.

Regular Checks

Regular checks are vital for scaffold safety. Inspect scaffolds before use. Look for any visible damage. Check for loose bolts and fittings. Ensure the scaffold is stable. Verify that wheels are locked. Regular checks help identify potential hazards early. This reduces the risk of accidents.

Repair Protocols

Repair protocols are essential for scaffold maintenance. Address any issues immediately. Use only qualified professionals for repairs. Ensure all parts meet safety standards. Replace damaged parts without delay. Document all repairs and inspections. This creates a reliable maintenance history. A robust repair protocol keeps scaffolds in top condition.

Training And Certification

Training and certification are crucial aspects of operating mobile scaffolds in construction, especially in Saudi Arabia. Proper training ensures safety and efficiency, while certification guarantees that workers are qualified to handle the equipment. The need for thorough training and certification becomes even more critical as mobile scaffolds can reach significant heights, posing risks if not handled correctly.

Worker Training Programs

Have you ever wondered how construction workers manage those towering mobile scaffolds? It’s all about rigorous training programs. These programs teach workers how to safely erect, use, and dismantle scaffolds. They include hands-on practice, ensuring workers are well-prepared for real-life scenarios.

Training sessions also cover emergency procedures. Imagine being on a scaffold and suddenly needing to evacuate—these programs prepare workers for such situations. A friend once shared how his training helped him handle a scaffold mishap without panic.

Certification Requirements

Certification is like a badge of honor for scaffold operators. It proves that you know the ins and outs of mobile scaffolds. To earn this certification, you must pass tests that assess your understanding and practical skills.

Think of certification as a passport to safer work environments. It ensures that only qualified personnel handle mobile scaffolds, minimizing accidents. In Saudi Arabia, these requirements are stringent, reflecting the high standards of construction safety.

Certification also includes regular updates. As technology advances, scaffold designs change, and certification keeps you in the loop. Have you updated your skills recently?

Case Studies In Saudi Arabia

Mobile scaffold height in Saudi Arabia is regulated for safety. The maximum allowed height is often 12 meters. Construction sites must ensure stability and compliance with safety standards to prevent accidents.

In the world of construction, mobile scaffolding is a crucial component, particularly in Saudi Arabia where skyscrapers dot the skyline. Understanding its maximum height and safe usage is essential for successful project execution. Let’s explore some real-life case studies from Saudi Arabia that demonstrate the effective use of mobile scaffold and what we can learn from them.Successful Implementations

In Riyadh, a leading construction firm successfully used mobile scaffolding to build a state-of-the-art commercial complex. The project required scaffolding to reach impressive heights safely. The team adhered strictly to safety regulations, ensuring each level was securely fastened before moving higher. This careful attention to detail prevented potential accidents and kept the project on schedule. Another successful project took place in Jeddah, where mobile scaffolding was used for a large-scale residential development. The construction team adopted a modular approach, which allowed for easy adjustments as the building progressed. By maintaining communication and conducting regular safety checks, they completed the project efficiently and safely.Lessons Learned

One major lesson from these projects is the importance of thorough planning. Before erecting scaffolding, it’s crucial to assess the site’s specific needs and challenges. This proactive approach can prevent costly mistakes and ensure the safety of workers. Another key takeaway is the value of regular safety inspections. In one project, a minor oversight was caught during a routine check, preventing what could have been a significant safety hazard. Consistent monitoring is not just a regulatory requirement but a practical necessity. Have you considered how these insights could apply to your own projects? Whether you’re working on a high-rise or a simple maintenance task, these examples emphasize the need for meticulous planning and unwavering commitment to safety. By applying these lessons, you can ensure your scaffolding projects in Saudi Arabia reach new heights—safely and successfully.

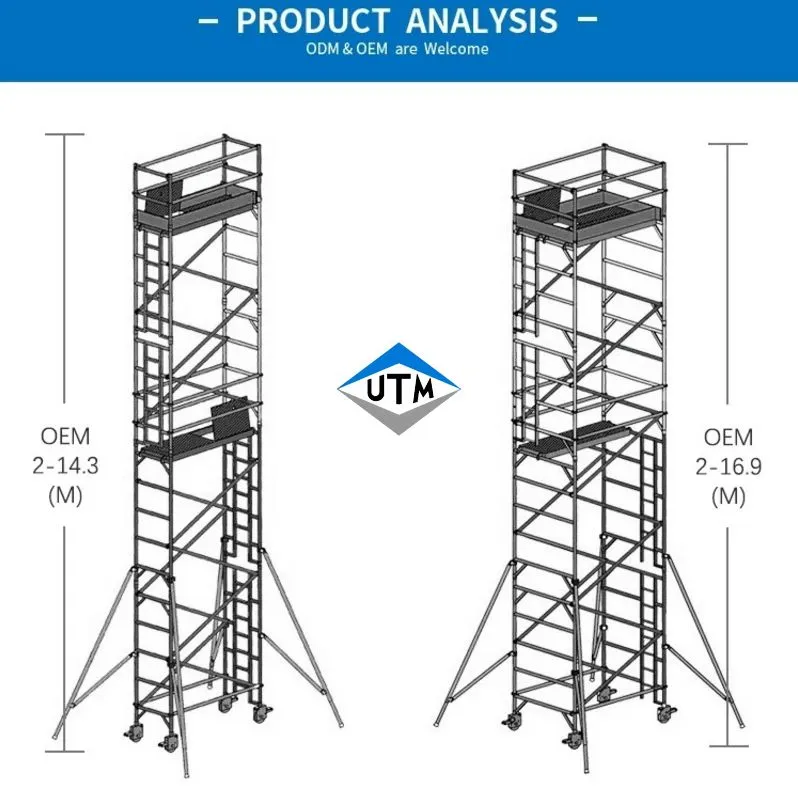

Credit: utmscaffold.en.made-in-china.com

Future Trends

When we talk about the maximum height of mobile scaffolds in construction in Saudi Arabia, it’s essential to look at future trends. These trends are not just about reaching higher but also about working smarter and safer. Let’s dive into what the future holds for mobile scaffolding with a focus on technological advancements and regulatory changes.

Technological Advancements

Technology is rapidly changing the construction industry. One big trend is using smart technology in mobile scaffolds. Imagine a scaffold that can monitor its stability and alert you if there is any risk of tipping over. This could significantly enhance safety.

Another exciting development is the use of lightweight, yet sturdy materials. These materials make it easier to construct and move scaffolds. They also contribute to better weight distribution, reducing the risk of collapse.

Additionally, modular scaffolding systems are becoming more popular. These systems allow you to easily add or remove sections. This flexibility can save time and reduce labor costs.

Regulatory Changes

Regulations are also evolving to meet the demands of modern construction. In Saudi Arabia, there is a growing focus on safety standards. New laws might require more frequent inspections and better documentation.

There could also be stricter rules about who can set up and dismantle scaffolds. This means more training and certification for workers, ensuring that only qualified people handle these tasks.

Changes in regulations often follow technological advancements. As new technologies become available, laws adapt to ensure they are used safely and effectively. Are you prepared to meet these upcoming regulatory changes?

Both technological advancements and regulatory changes are shaping the future of mobile scaffolding. By staying informed, you can ensure your projects are not only compliant but also at the forefront of innovation. What steps will you take to prepare for these changes?

Frequently Asked Questions

What Is The Maximum Height For Mobile Scaffolding?

Mobile scaffolding typically reaches a maximum height of 12 meters for outdoor use. Indoors, it usually goes up to 8 meters. Always adhere to manufacturer guidelines for safety. Proper setup and usage are crucial for ensuring stability and preventing accidents.

Regular inspections help maintain safe working conditions.

What Is The Maximum Height Limit When Moving A Mobile Tower?

The maximum height limit for moving a mobile tower is typically 30 meters. Always check local regulations for specific requirements.

What Is The Height Limit For Scaffolding?

The height limit for scaffolding varies by regulation. OSHA typically allows up to 125 feet for supported scaffolds. Always check local regulations.

What Is The Highest You Can Have A Scaffold Tower?

The maximum height for a scaffold tower is 12 meters outdoors and 8 meters indoors, with proper safety measures.

Conclusion

Understanding the maximum height for mobile scaffolds in Saudi Arabia is crucial. It ensures safety and compliance with regulations. Always use proper equipment and follow guidelines. This keeps workers safe and projects on track. Stay informed and prioritize safety on your construction site.

This knowledge protects your team and meets legal standards. Remember, safety first.